Sealpac UK & Partners excel in providing comprehensive end-to-end solutions. Our expertise ensures reliable design, installation, and maintenance of production lines across multiple industries. Challenge us – you'll be glad you did!

Find out what your journey with us will look like!

Sealpac UK & Partners excel in providing comprehensive end-to-end solutions. Our expertise ensures reliable design, installation, and maintenance of production lines across multiple industries.

Find out what your journey with us will look like!

-

Consulting

We’re proud of our proven track record providing bespoke automated production line solutions to all sectors in the food industry. With our engineering and industry knowledge and experience, along with project management expertise, our consultancy service has helped customers find food production solutions tailored exactly to their needs. Our team work hand in hand with you from start to finish, covering all sectors including meat, poultry, fish, seafood, dairy, ready meals, snacks, convenience, pet food and confectionary.

Find out more -

Delivering

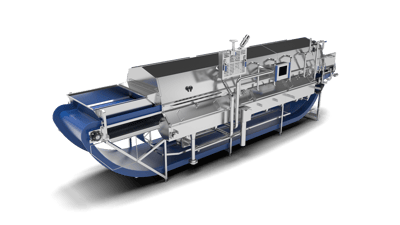

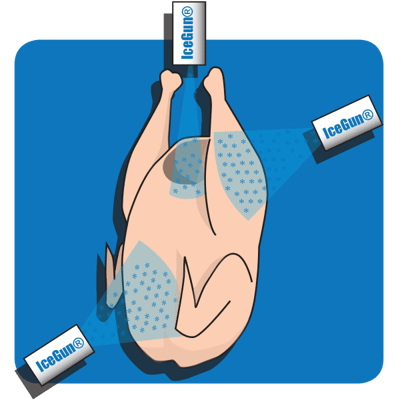

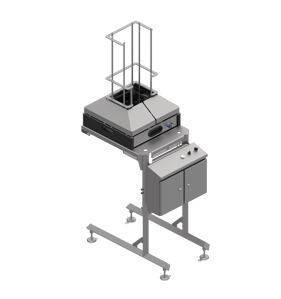

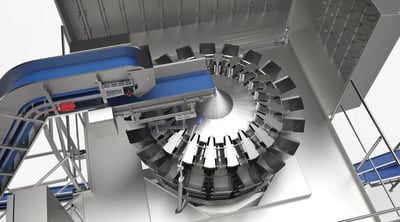

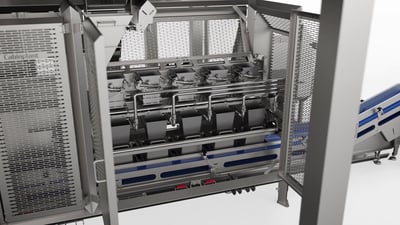

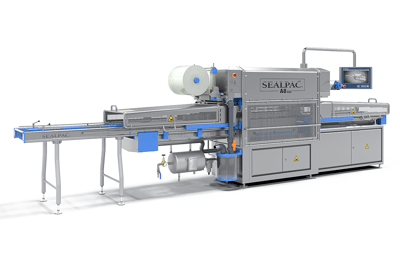

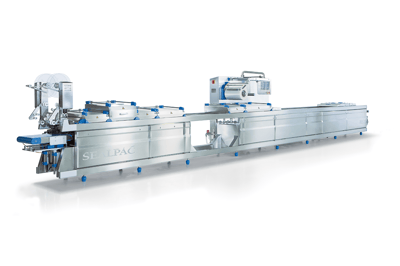

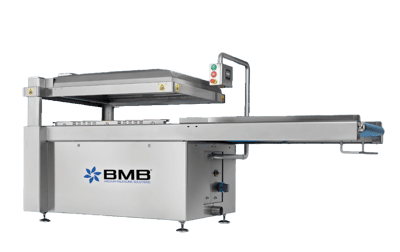

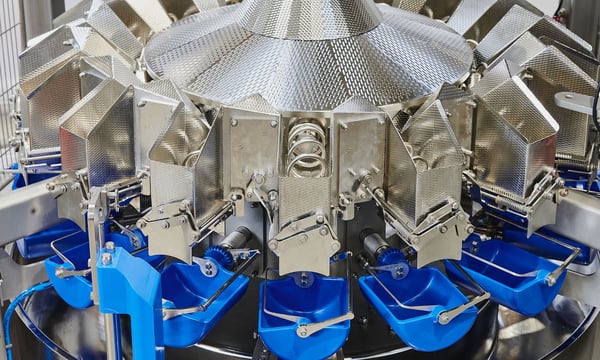

Our network of trusted partners have an impressive range of food production machinery including sorting, processing, weighing, depositing and packaging equipment. Packaging machinery includes Traysealers, Thermoformers, Bag Makers, flowrapping and vacuum packing. The end of line solutions take care of quality control including checkweighers, Xray, metal detection, and combinations with seal inspection and leak detection. Finally, the case packing and palletising solutions take care of automating your production line right up to the despatch door.

-

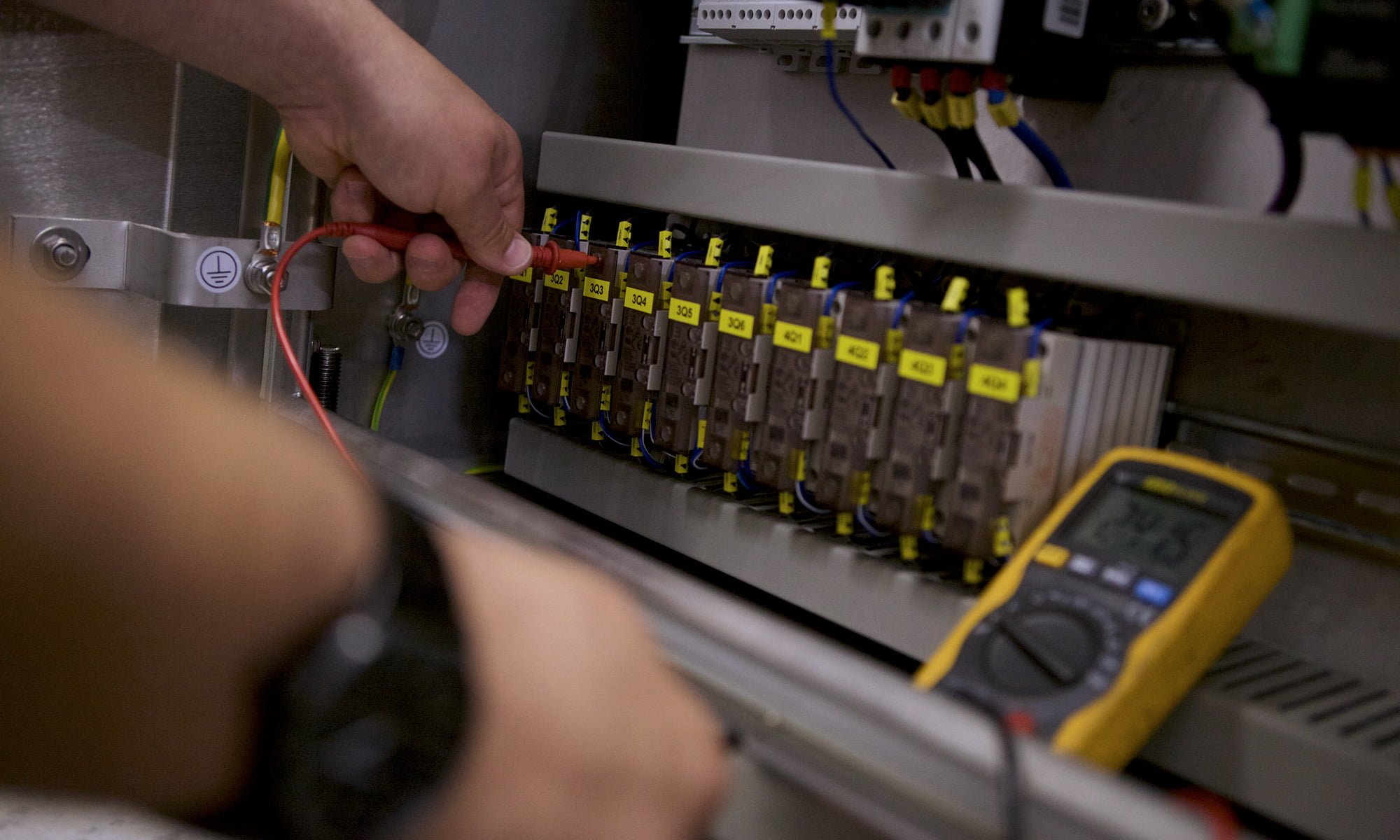

Supporting

We recognise the significant investment you make on your food production lines. That’s why our team of engineers are strategically placed in the UK and Ireland to be there when you need them. In addition, we stock a comprehensive range of spare parts in the warehouse, so you can order parts directly to your door. Our tailor made service contracts are designed to save you time, cost and keep you running efficiently and smoothly all year round. The engineering team is always on hand to provide technical support over the phone or where necessary, an emergency call out.

Our Expertise

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

In partnership with

Consultancy services

Combining our knowledge and experience with best practice solutions and class leading food machinery technology.

Machinery solutions

Aftersales support

Class leading after sales covering the UK & Ireland including machine maintenance, production line optimising, training, upgrades and spares packages.

The latest from our blog

Celebrating a Fantastic Year: Wrapping Up 2025

As the festive season draws near and calendars flip towards 2026, it feels like the perfect moment to pause and celebrate everything we’ve achieved...

Continue reading

Skewering on the Rise: Why UK & Ireland Producers Are Investing in Automation

Demand for skewered products—from premium BBQ lines and ready-to-cook meals to innovative plant-based options—is soaring across the UK and Ireland....

Continue reading

Produce Perfected with Sealpac UK & Partners

Globally, around one-third of all food produced is lost or wasted — with fresh fruits and vegetables facing the highest loss rates, between 25% and 50%,...

Continue reading

Do you have a project that you’d like to discuss?

Our experts are on hand to help maximise the efficiency of your line. Let’s see what we can do for you.

-

Case Study

Automating Skewer Production with the MIVEG 7200

The Challenge A major UK food manufacturer faced growing pressure to scale up its BBQ skewer production. Their existing line relied heavily on manual...

Read the full Case Study

-

Case Study

Installing A High-Speed Salad Layering Line With Sealpac UK and Partners

The Challenge A customer had recently taken on the production of layered salad and pasta products from another supplier. These were complex and tricky...

Read the full Case Study

-

Case Study

Automating Noodle Weighing and Distribution

The Challenge The customer faced several challenges with their existing noodle weighing and distribution system. The process required multiple operators...

Read the full Case Study