BMB Vacuum Machine Range

We partner with BMB to offer automatic belted and double chamber vacuum machines. Belted vacuum machines use a continuous belt to automate the packaging process, reducing manual labour. Double chamber machines are ideal for vacuum or modified atmosphere packaging of large food and non-food items. Both machines are designed for high efficiency, intensive use, and ensure excellent sealing quality for high production demands.

Table of Contents

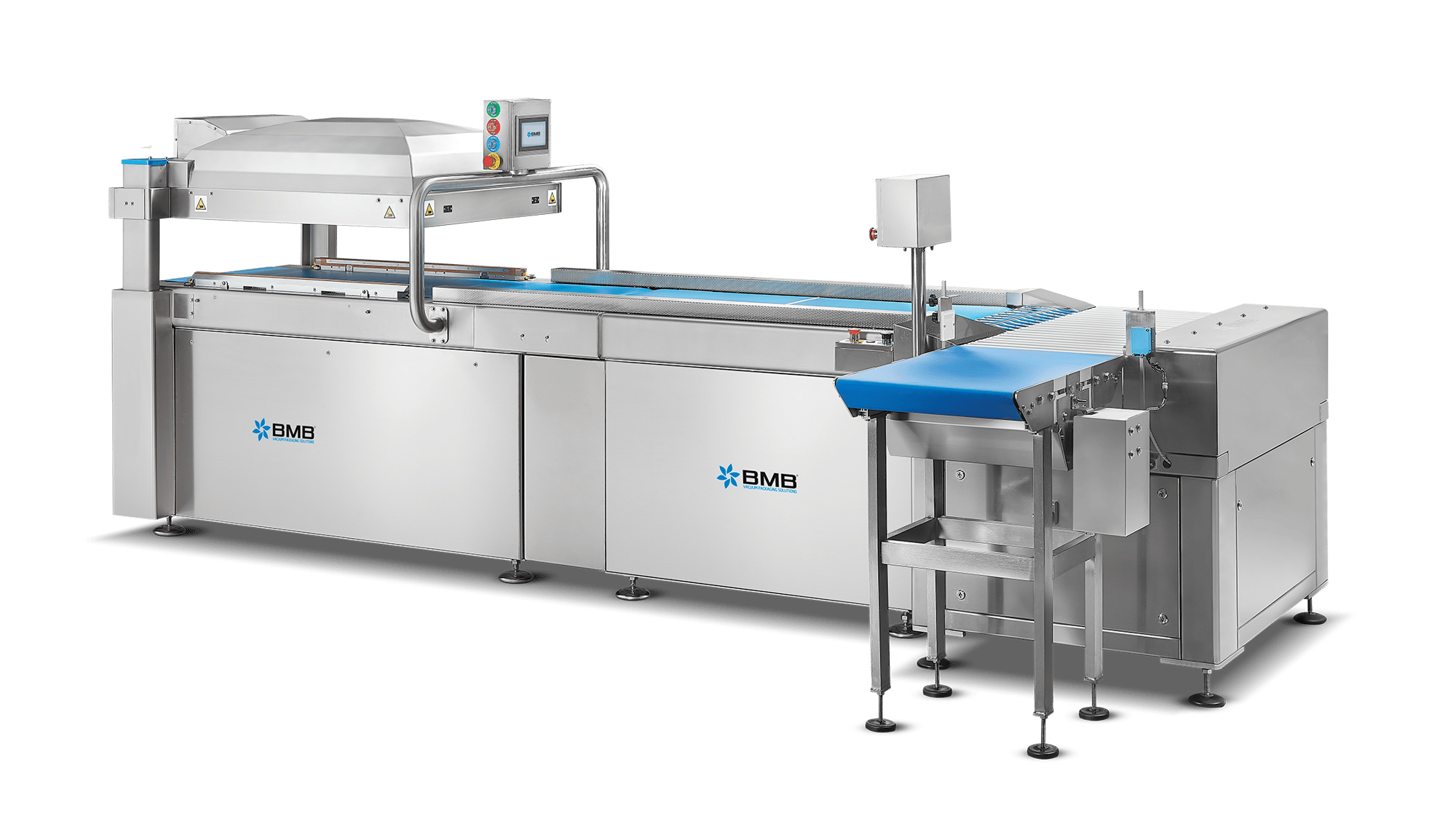

The Conveyor Pro

The Conveyor Pro series belt vacuum packaging machines are fast, versatile, and built for long-term use. They enable automatic, continuous packaging of both food and non-food products in bags, ideal for large batch sizes.

- Automatic feeding belt separates loading and packaging processes.

- Products can be placed on the inlet belt during the vacuum cycle, manually or via automated systems like robots or handling belts.

- Models differ by the number, length, and spacing of sealing bars, which determine the vacuum chamber size.

- Hood can have three sealing bars, maximising chamber space, with loading possible from both sides.

- Vacuum pump is selected based on customer needs, with an option to connect to centralised vacuum systems.

- Precise vacuum control is ensured by an absolute sensor.

- Made from AISI 304 stainless steel, featuring easy cleaning, quick belt release, automatic water drainage, and an IP67/NEMA 4 rated electrical panel.

- Additional options include:

- Soft-air technology for controlled re-entry.

- Adjustable sealing bars for products of varying sizes.

- "Twin Seal" or "Wide Seal" bi-active sealing.

- Scrap cutting systems with automatic waste suction.

- Compatible with various bag types (PA/PE, OPA/PP, Aluminium) for smooth or embossed vacuum, heat-shrinkable, and different thicknesses, with adjustable sealing intensity on each model.

The Conveyor Pro SP

The Conveyor Pro SP series belt vacuum packaging machines are fast, versatile, and built for durability. They enable automatic, continuous packaging of both food and non-food products in large batch sizes..

- Automatic infeed belt separates loading from packaging, allowing products to be positioned during the vacuum cycle, either manually or with automated systems like robots or handling belts.

- Models vary by sealing bar number, length, and spacing, affecting vacuum chamber size. Some models feature three sealing bars and can be loaded from either side.

- The vacuum pump is chosen based on customer requirements and can connect to centralised vacuum systems. Precise control is provided by an absolute sensor.

- Constructed from AISI 304 stainless steel, with easy cleaning, quick belt release, automatic water drainage, and an IP67/NEMA 4 electrical panel.

- Optional features include:

- Soft-air technology for controlled re-entry

- Adjustable sealing bars for different product sizes

- "Twin Seal" or "Wide Seal" bi-active sealing

- Scrap cutting systems with automatic waste suction

- Compatible with various bag types (PA/PE, OPA/PP, aluminium) and thicknesses, including smooth, embossed, and shrinkable, with adjustable sealing intensity.

The Conveyor MAP

The Conveyor MAP automatic chamber belt vacuum packaging machine is both efficient and adaptable, designed for long-lasting performance. Ideal for freshly baked products like pizza, piadina, crescia, pinsa, fresh pasta, and other fresh items, it efficiently packs large batches of food or non-food products into bags automatically and continuously.

- The new Conveyor MAP is patented and the first automatic chamber belt vacuum machine with direct inert gas injection for protective atmosphere packaging.

- Automatic feeding belt separates loading from packaging, allowing product placement during the vacuum cycle, either manually or with automated systems.

- Guarantees controllable O2 levels below 0.01%* with high vacuum and direct inert gas injection based on product type and desired shelf life.

- Continuous cycle operation with minimal labour.

- Eliminates product loading downtime and manual product removal, with packaged items continuing onto roller or motorised belts for further operations (e.g., metal detection, labelling)

- Customisable vacuum pump options and precise vacuum control via an absolute sensor.

- Made from AISI 304 stainless steel, featuring easy cleaning, quick belt release, automatic water drains, and IP67/NEMA 4 insulated electrical panel.

- Optional features include:

- Soft-air technology for controlled re-entry

- Adjustable sealing bars for different product sizes

- "Twin Seal" or "Wide Seal" bi-active sealing

- Scrap cutting systems with automatic waste suction

- Ideal for fresh-baked goods, fresh pasta, and a variety of food/non-food products in eco-friendly or traditional bags (PA/PE, OPA/PP, aluminium) of different thicknesses.

The Double Chamber

The Conveyor Pro SP series belt vacuum packaging machines are fast, versatile, and built for durability. They enable automatic, continuous packaging of both food and non-food products in large batch sizes..

- Automatic infeed belt separates loading from packaging, allowing products to be positioned during the vacuum cycle, either manually or with automated systems like robots or handling belts.

- Models vary by sealing bar number, length, and spacing, affecting vacuum chamber size. Some models feature three sealing bars and can be loaded from either side.

- The vacuum pump is chosen based on customer requirements and can connect to centralised vacuum systems. Precise control is provided by an absolute sensor.

- Constructed from AISI 304 stainless steel, with easy cleaning, quick belt release, automatic water drainage, and an IP67/NEMA 4 electrical panel.

- Optional features include:

- Soft-air technology for controlled re-entry

- Adjustable sealing bars for different product sizes

- "Twin Seal" or "Wide Seal" bi-active sealing

- Scrap cutting systems with automatic waste suction

- Compatible with various bag types (PA/PE, OPA/PP, aluminium) and thicknesses, including smooth, embossed, and shrinkable, with adjustable sealing intensity.

How can you benefit from our experience?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.