Cabinplant Multihead Weigher Range

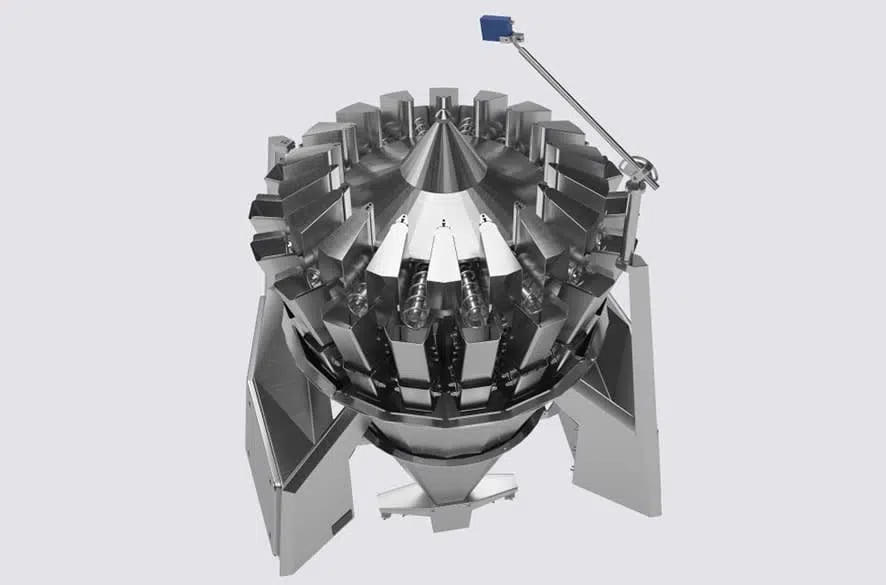

Multihead Weigher with Screw Feeding

Unique and Patented Solution in handling Sticky Products

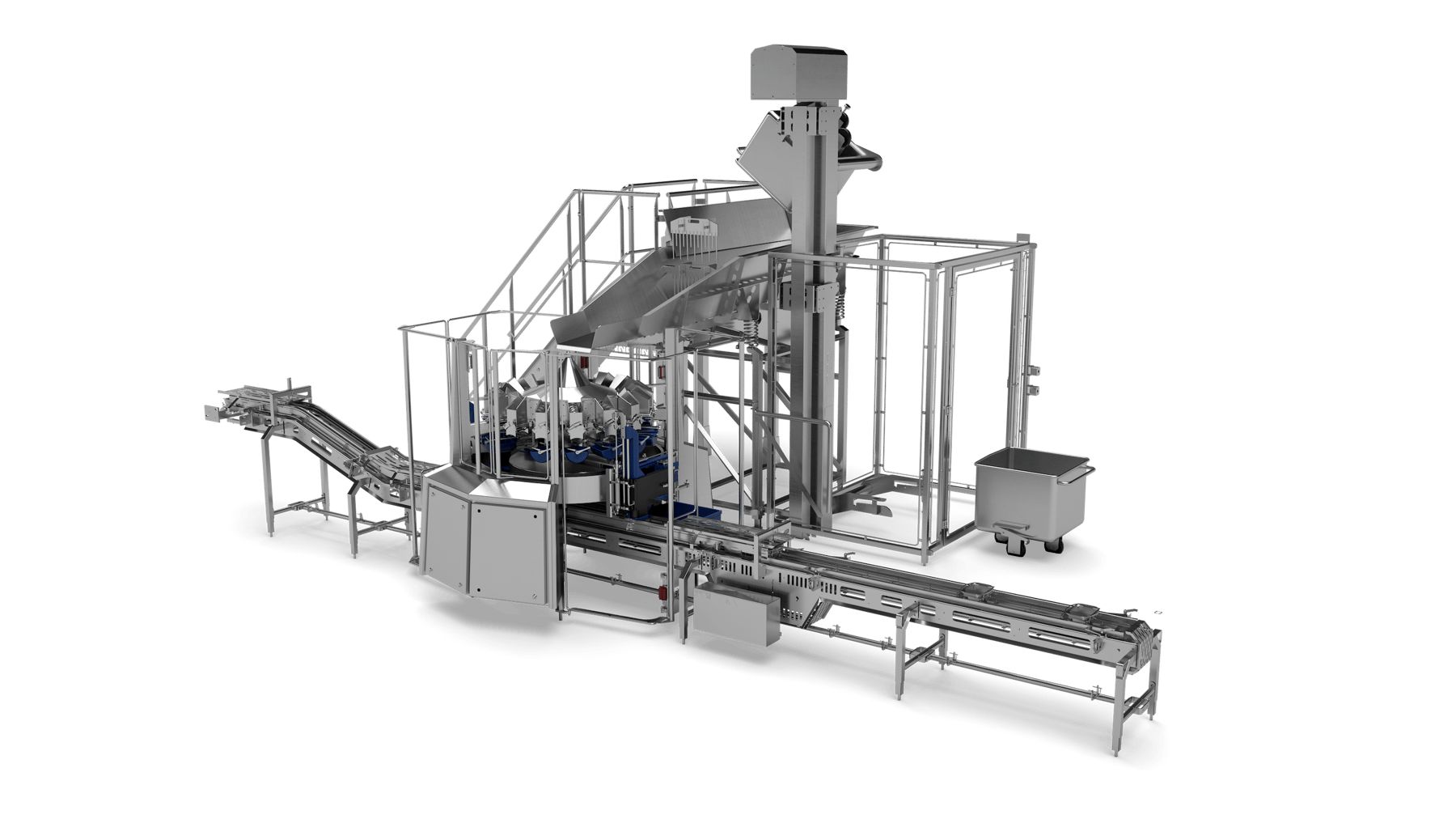

The Cabinplant screw-feeding multihead weigher has been granted several patents worldwide for its unique ability to handle difficult products, especially those that are fragile, wet or sticky. This flexible machine can be adapted to cater for many different needs. For example, rollers can be integrated between the individual channels when handling long products. The screw-feeding multihead weigher features continuous weighing, rotating cones on top, and screw dosing time that automatically adjusts as a function of partial portion weighing. The screw feeding system dispenses the product with special screws into assembling pans, and sensor gates ensure this is optimal. This ensures feeding of only one piece of product into each pan. As a result, industries such as meat, poultry, seafood, vegetables, confectionery, and ready meals have been able to enhance weighing accuracy significantly and substantially reduce give-away costs.

Type of weighing:

- Single or multiple weighing

- Flow weighing

- Floating set-point weighing

- Single dynamic weighing (SDW)

- Dual dynamic weighing

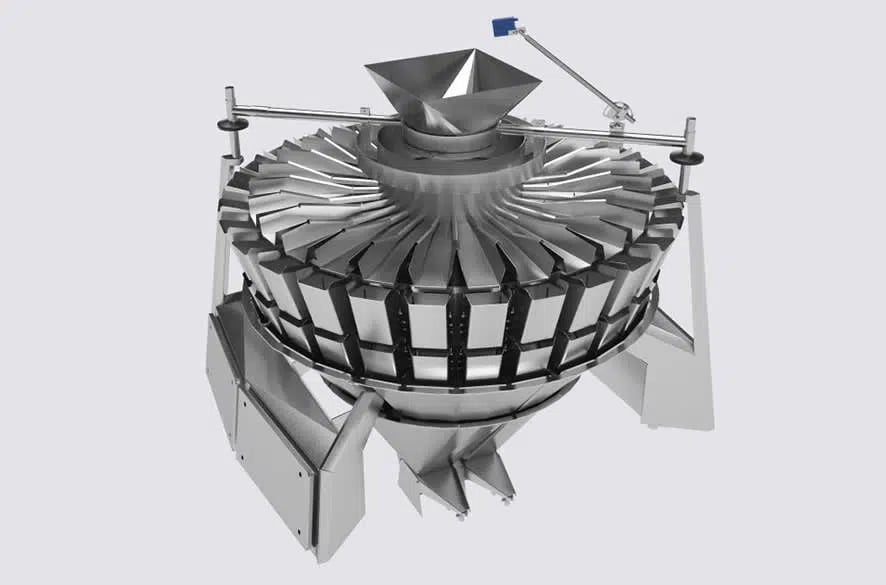

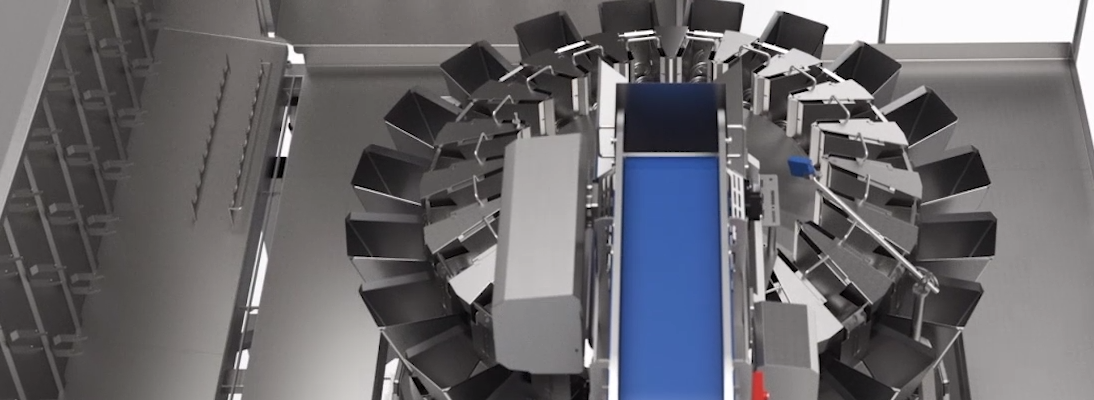

Multihead Weigher with Vibratory Feeding

Precise and Rapid Weighing of Difficult and Delicate Products

The multihead weighers with vibratory feeding have been designed to meet the increasing demand for accuracy and speed in weighing challenging products, including vegetables, fruits, fish, and ready meals. The traditional multihead weigher uses vibration to transfer and distribute product into the weighing pans. The top cone conveys the product to the vibrator chutes by means of vibration. These vibrator chutes, regulated by time and amplitude, effectively guide the product into the assembling pans. The multihead weigher can be divided into up to four distinct product zones or configured to create precise blends of selected products.

Type of weighing:

- Single or multiple weighing

- Flow weighing

- Floating set-point weighing

- Multiple target weighing

- Mix weighing

Features & benefits

- No give-away when handling small negative tolerances

- Specially adapted product contact materials for handling sticky products

- Minimum noise level

- Minimum maintenance

- Easy cleaning

- Touch operator panel

- Continuous weighing

- Vibration cone on top

- Vibration dosing time automatically adjusted as a function of partial portion weighing

- Tailor-made design according to customer request

- Special surface for frozen and sticky products

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.