Thor Ice Solutions

A Revolutionary Cooling Technology

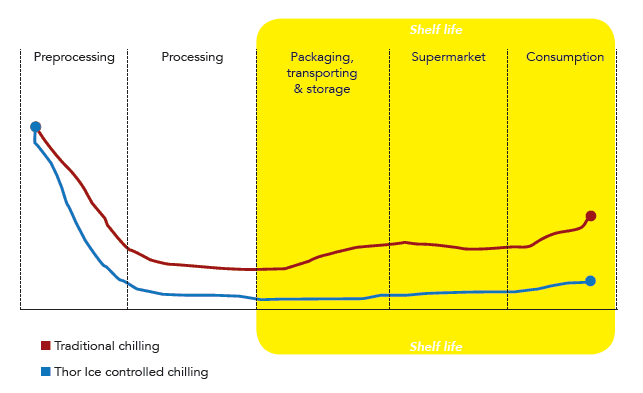

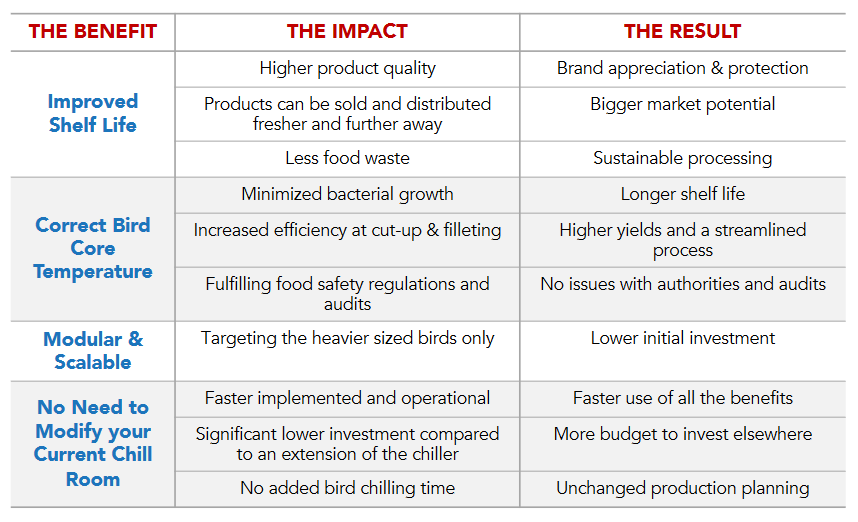

Our partner, Thor Ice has developed a unique set of technologies for producing, storing, and distributing slurry ice. These technologies allow efficient and complete chilling of fresh products like fish, poultry, and meat, throughout the entire food value chain: from processing through distribution to consumption. With this technology, slurry ice can be controlled and distributed more easily and productively than ever. That is why the technology has proven to be more effective than any other chilling method — cold air, flake ice, chilled seawater, and traditional ice cubes.

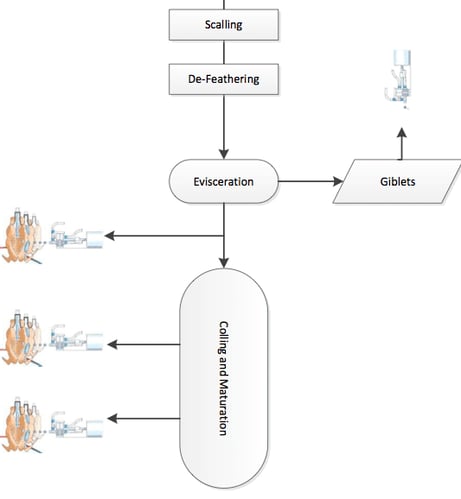

The modular Thor Ice technology platform is designed to seamlessly integrate with existing chilling infrastructure, enhancing overall efficiency. Utilizing specialized spray nozzles, known as IceGuns®, slurry ice is applied both internally and externally to products as they progress through production. The IceGuns® are engineered to dispense slurry ice at precise concentrations, durations, and temperatures to optimize cooling efficiency. The quantity and placement of IceGuns® are customized to individual processes and programmed to achieve specific objectives.

The industry is increasingly focusing on bacterial counts, energy costs, and challenges posed by oversized poultry. Thor Ice offers cost-effective retrofit and bolt-on systems that are fully controllable, saving energy and accelerating production. These systems yield quick returns on investment, typically within a year, and are easily integrated into existing setups, avoiding the need for significant investments in chilling chambers. Our poultry processing solutions cater to producers of all sizes, developed in collaboration with European poultry producers, food institutes, and scientists, offering customizable options to meet individual preferences.

The IceGun® solutions targets specific areas to ensure rapid and effective chilling. Those area include:

- Inside the carcass

- On the breast

- Hard to reach crevasses in

the skin

the skin - Behind the neck area

- On and behind drumsticks

- Rapidly reach lower temperatures and maintain them all the way to the consumption.

- Deliver rapid chilling and lower temperature that will reduce bacteria growth and extend shelf life of products.

- Increase production capacity without making costly modifications to the existing chilling chamber and processing line, as the system works as a plug-in into existing systems.

- Keep the moisture inside the bird by chilling rapidly.

- Chilling from the inside will increase the total area of the bird to be chilled.

- Chill before the blast/spiral freezer and ensure faster freezing time and reduce costs.

Fish processing, whether on land or at sea, requires meticulous temperature control. Slurry ice is employed in land-based processing, either in bins or applied directly onto fish on conveyor belts, ensuring a consistent low temperature throughout the process. By the final stage, the raw product maintains its low temperature from catch chilling to packaging.

Fish processing, whether on land or at sea, requires meticulous temperature control. Slurry ice is employed in land-based processing, either in bins or applied directly onto fish on conveyor belts, ensuring a consistent low temperature throughout the process. By the final stage, the raw product maintains its low temperature from catch chilling to packaging.

Fisheries, 5 Tons or More

Proper chilling and handling significantly impact fish quality, whether it's frozen or fresh. Fish should reach near or below 0°C within the first hour after being caught, ideally achieved through rapid chilling with slurry ice. The quality of the flesh and shelf life directly depend on the initial handling within this crucial hour.

- Extended shelf life

- Reduced gaping

- Delay of rigor (from catch)

- Extended time of rigor

Fisheries, 5 Tons or Less

Slurry ice benefits are now accessible for smaller uses with Thor Ice's small series. This enables smaller boats to transport fresher raw materials ashore. Slurry ice enhances the quality of whitefish, pelagic, shellfish, and on-shore processing effectively. For fishermen and vessel owners, bin chilling offers the fastest and most efficient chilling available today. Slurry ice also extends the shelf life of raw products, enabling longer stays at sea.

Slurry ice benefits are now accessible for smaller uses with Thor Ice's small series. This enables smaller boats to transport fresher raw materials ashore. Slurry ice enhances the quality of whitefish, pelagic, shellfish, and on-shore processing effectively. For fishermen and vessel owners, bin chilling offers the fastest and most efficient chilling available today. Slurry ice also extends the shelf life of raw products, enabling longer stays at sea.

- Low investment cost

- Rapid, controlled chilling

- Increased product quality

- Low power consumption

- Single-phase or three-phase

- Can be connected to existing ice machines

- Powered by electicity or hydraulics

In the industry, there's a growing focus on bacterial levels, energy expenses, and weight loss in current production setups. Thor Ice has introduced retrofit and bolt-on systems that are both controllable and cost-effective, cutting down on energy usage and boosting production speed while enhancing operational efficiency and sustainability. Typically, the investment pays off in less than a year. This approach satisfies producers by sidestepping hefty investments in chilling infrastructure, as Thor Ice solutions seamlessly integrate into existing setups, enhancing chilling outcomes.

Our systems cater to producers of all scales, utilising controlled slurry ice for chilling and offering a non-disruptive, cost-effective solution that improves chilling without major process overhauls. Developed in collaboration with leading European poultry producers, food institutes, and scientists, Thor Ice systems come in various sizes, adaptable to each client's needs.

Chilling in Primary, Secondary and Further Processing

Ice slurry can be used in almost any area of the processing cycle, due to its versatile characteristics. The ice can be pumped anywhere in the factory and used in various ways:

- In the chilling room, targeting areas that need rapid chilling to stop weight loss.

- Chilling smoked and cooked pork to reduce weight loss in processing.

- Applied with IceGuns® in areas where quick chilling is needed.

- Applied indirectly, as rapid chilling medium that does not touch the surface directly.

Benefits

- Rapidly reach lower temperatures and maintain them all the way to the consumption.

- Deliver rapid chilling and lower temperature that will reduce bacteria growth and extend shelf life of products.

- Increase production capacity without making costly modifications to the existing chilling chamber and processing line, as the system works as a plug-in into existing systems.

- Keep the moisture inside the meat by chilling rapidly.

- Chill before the blast/spiral freezer and ensure faster freezing time and reduce costs.

- Reach lower temperature before packaging and storing of products.

The swift chilling process with slurry ice affords food producers the opportunity to streamline handling during processing, thereby reducing labor, waste disposal, and energy expenditures.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.