.jpg?width=1800&name=Checkweigher_HR600_Det_01_2022_10_20%20(1).jpg)

Checkweigher Systems

Our checkweighers, equipped with interconnections and data collection software, communicate seamlessly with external systems to meet Industry 4.0 requirements. Additionally, the entire range has options for remote assistance management, enabling quick interventions that reduce maintenance costs. The operator interface, designed with a touchscreen 12” panel, it’s easily usable from the inline personnel, allows the total management of the system: from the work’s set up to the various features of the single products to control with the relative acceptance parameters, storable up to 254 product recipes. We can build our machines fully to retail specification.

Checkweigher for Medium - Small Products

Checkweighers for small formats are designed for high-speed lines requiring high-performance, precise weight measurement of lightweight products. Equipped with high-quality components, these systems ensure consistent accuracy with features such as self-calibration, touchscreen control, multi-level password access, brushless motors, data collection software, and bidirectional management for enhanced usability and durability.

Built with AISI 304 stainless steel frames and hard-anodised aluminium modules, these checkweighers are engineered to withstand harsh industrial environments and integrate seamlessly into production lines.

The modular component design offers flexibility, allowing easy adaptation for different product formats and sizes as production needs evolve.

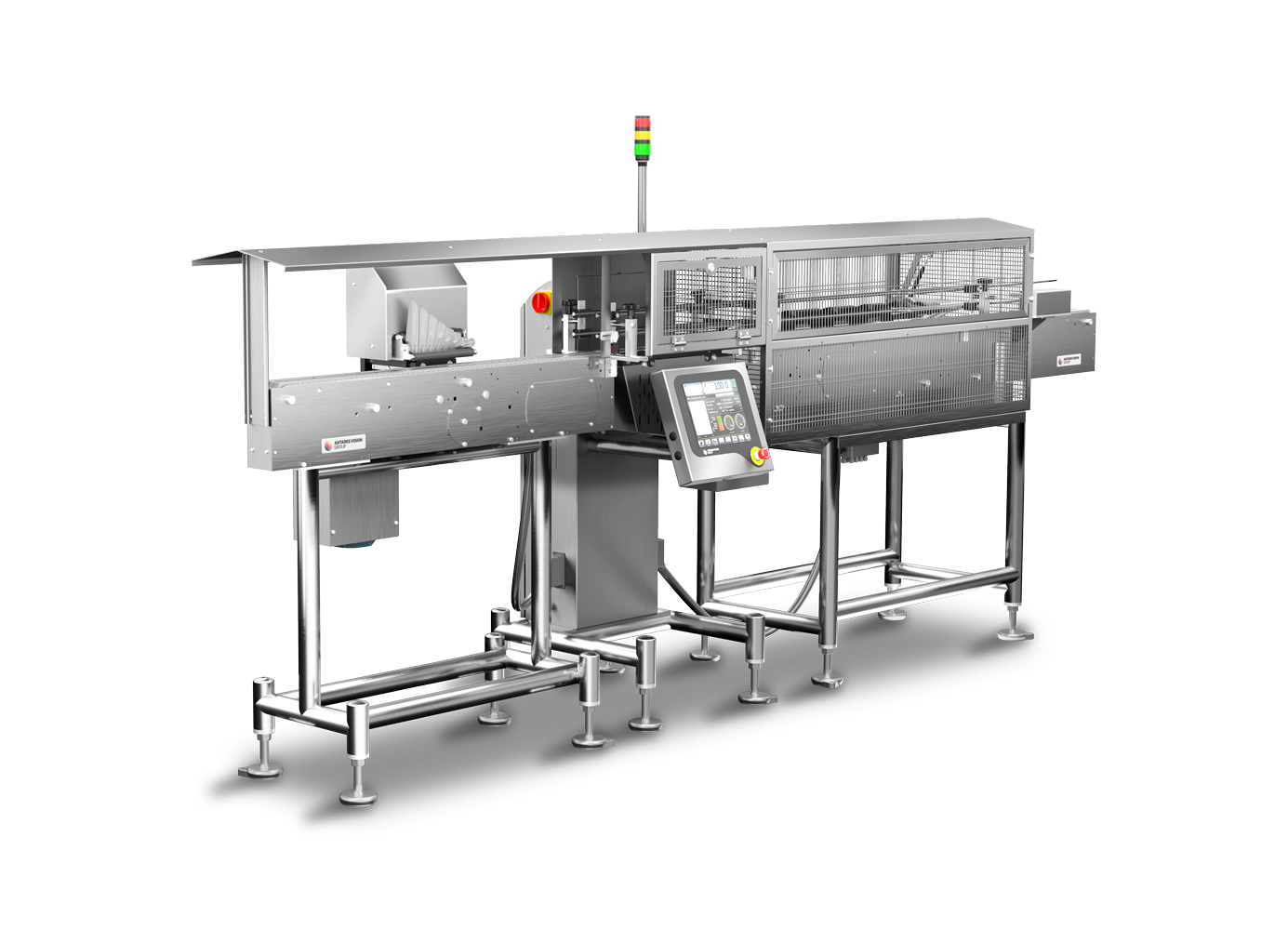

Checkweigher for Medium - Large Products

Checkweighers for medium to large formats are designed for reliable control of both primary and secondary packaging, verifying declared weight and ensuring completeness. Equipped with brushless motors, planetary gearboxes, and pulley-free rollers, these systems manage large, heavy items—such as bags and boxes—while maintaining high productivity and efficiency.

Constructed with AISI 304 stainless steel for the main support structure and hard-anodised aluminium for the product movement modules, these checkweighers are durable and capable of integrating smoothly into demanding industrial environments.

The modular component design enhances flexibility, allowing users to adapt easily for new product formats and sizes as production requirements evolve over time. This adaptability, along with premium finishes and materials, ensures long-term performance in a range of settings.

Heavy Load/End-Of-Line Checkweigher

This end-of-line checkweigher is designed for weight and completeness checks on boxes, bags, crates, and wrapped packages. Built for heavy loads and large dimensions, it operates reliably in harsh environments. Equipped with single or double load cells, it ensures stability and efficiency. Available with multi-level spaced belts and ejection options, as well as conveyor belt or modular chain configurations.

Optional features include code reading, open flap detection, and wet case detection.

The AISI 304 stainless steel frame and hard-anodised aluminium movement modules make it ideal for industrial production settings, even in challenging conditions. The modular design provides flexibility, allowing easy adaptation to different product formats and sizes as requirements change over time.

Checkweighers with chain conveyors and skid

These checkweighers feature a chain and skid conveyor system designed to handle products of various shapes and sizes, thanks to a transport scheme with adjustable width. They can be equipped with an infeed screw for product cadence and spacing, with micrometric adjustments, making them ideal for jars, plastic bottles, and cans. High-speed line configurations are also available, and the system’s robust construction ensures suitability for harsh environments, open products, and areas requiring frequent cleaning.

The modular design of the components allows for greater flexibility, enabling users to easily adapt the system to accommodate new product formats with different sizes and features over time, without the need for a complete redesign.

Special Checkweighers

We also offer customised checkweighers tailored to meet the specific needs of our clients. These specialised systems are designed to accommodate unique product requirements, operational conditions, and production environments.

- Checkweighers with side belts: Ideal for vertical and unstable formats in high-speed lines.

- Dual lane checkweigher: Allows simultaneous weight checks on two lanes, eliminating the need for two systems.

- Multi-lane checkweigher for packaged products: For checking various packaged products like bags, trays, and cases.

- Checkweighers for raw dough: Optimises portioning for consistent weight in finished dough products.

- Dynamic weighing module: For OEM applications in filling, packing, and cartoning machines, with custom electronics.

- Multi-lane checkweighers for unpackaged products: Designed for products like bread, pizzas, and dough, handling raw, pre-cooked, fresh, and frozen items.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.