Sealpac Tray Denesting Range

SEALPAC's pick and place denesters provide exceptional accuracy for placing trays onto a Traysealer conveyor. Available in single and double lane systems, they pick multiple trays simultaneously and synchronize seamlessly with the production line for optimal efficiency. Requiring only an electrical power connection, these units feature a servo drive for unmatched denesting precision. Each denester is easily integrated into both new and existing food production lines.

AS-RS Servo Diagonal Denester

SEALPAC’s AS-RS diagonal denester is ideal for small to medium production outputs. With a magazine stack height of 1,100 mm and an optional second magazine, it efficiently places a large number of trays onto the in-feed conveyor.

Benefits at a glance

AS-LS Servo Linear Denester

SEALPAC’s AS-LS linear denester is ideal for high-output applications. Mounted over the in-feed conveyor to save space, it uses suction cups to smoothly place trays onto the conveyor. The system easily adapts to different tray formats by swapping out the mask and suction unit.

MA-S 800/800e Servo Magazine Denester

Compact and fully electronic, the SEALPAC MA-S800/MA-S800e magazine denester accommodates a wide range of tray formats and comes in both single-lane and double-lane versions. With servo-driven axes, it provides versatile motion sequences for highly reliable denesting. The MA-800e version features an ergonomic design that ensures easy access to the tray magazine.

Benefits at a glance

- Innovative airless concept: nothing other than electricity required

- Compact design

- Maintenance-friendly, lubrication-free construction

- Easy integration into the packaging line, simple updating of existing lines

- Unlimited variety of motion sequences thanks to axes with servo drive

MA-S 1200/1200e Servo Magazine Denester

Compact, fully electronic, and with increased capacity, the SEALPAC MA-S1200/MA-S1200e magazine denester accommodates more trays and boosts the number of trays denested per cycle with its larger magazine. Available in both single and double lane versions, it features servo-driven axes for versatile motion sequences, ensuring highly reliable denesting. The MA-S1200e version also offers an ergonomic design for easy access to the tray magazine.

Benefits at a glance

- Innovative airless concept: nothing other than electricity required

- Compact design

- Maintenance-friendly, lubrication-free construction

- Easy integration into the packaging line, simple upgrade of existing lines

- Unlimited variety of motion sequences thanks to axes with servo drive

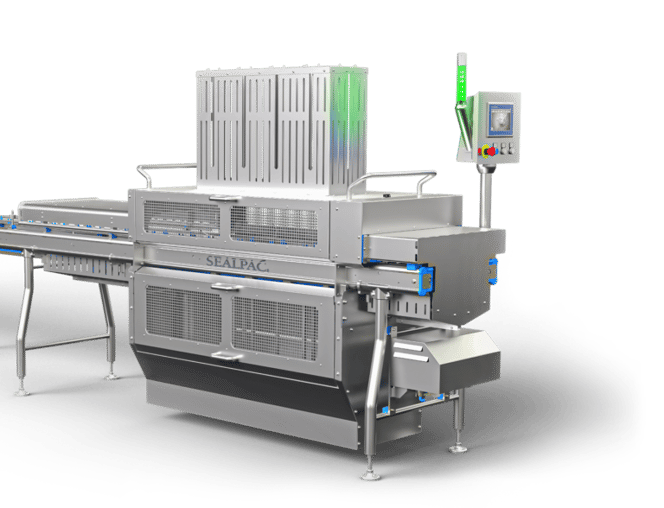

MA Servo Magazine Denester

SEALPAC’s MA magazine denester is ideal for high-output applications. With its extra-large magazine featuring a 1,000 mm stack height, it efficiently positions large quantities of trays onto the in-feed conveyor each cycle. Available in a double lane option, the MA denester can also handle two different tray formats simultaneously.

Benefits at a glance

- Highest speed and output

- Suitable for all SEALPAC Amax-series traysealers

- Extra-large magazine

- Optional: magazines for different tray sizes

- Servo-driven for optimal control

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.