MIVEG Automated Skewering System Range

MIVEG's Automated Skewering Systems deliver unmatched efficiency and high output, producing up to 7.5 million kebabs per season with advanced, reliable solutions. These solutions come with modular upgrades like automated loading and convenient Clean-in-Place capabilities.

Table of Contents

Automation Vs Traditional Skewering: Comparison of output:

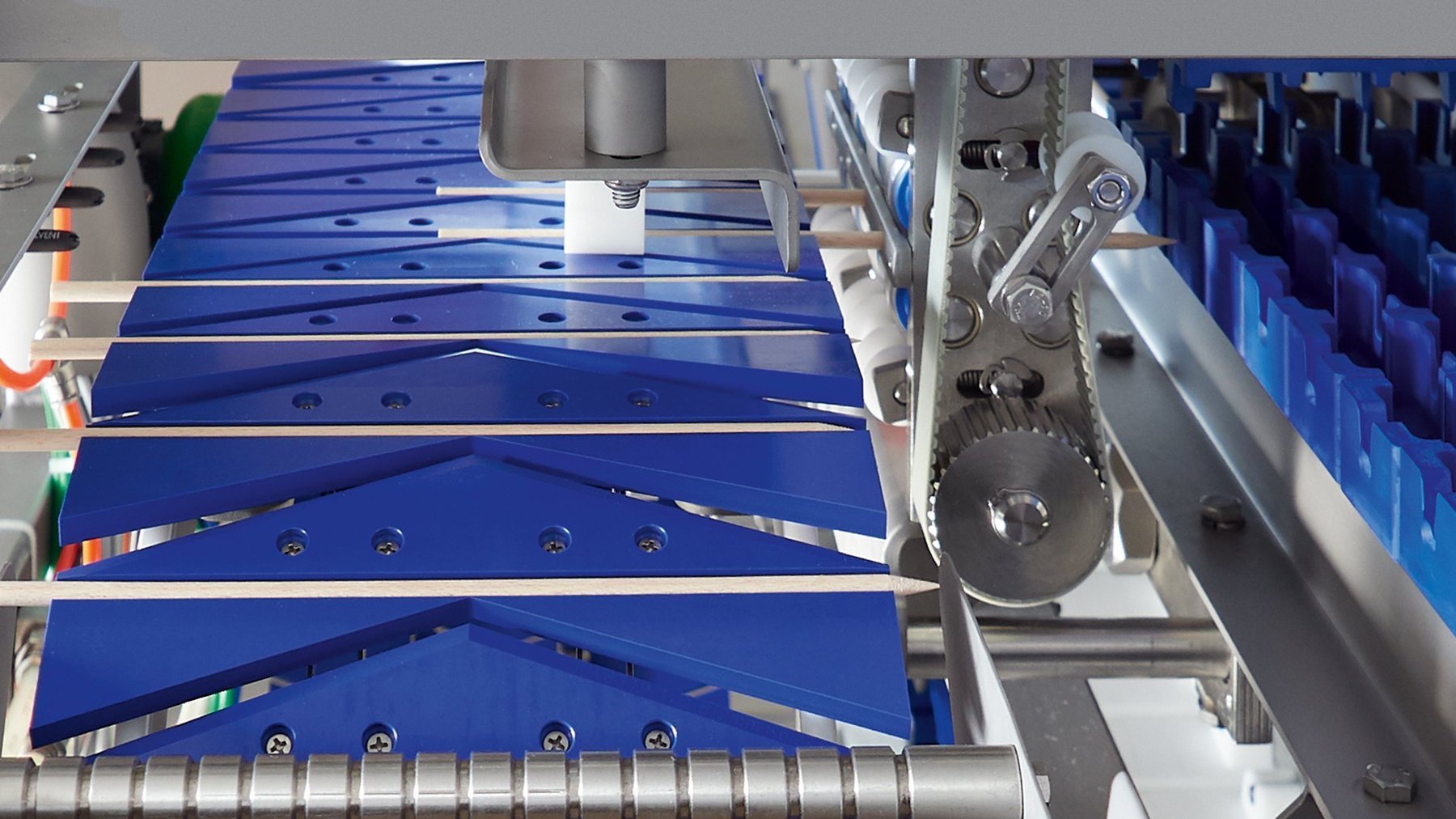

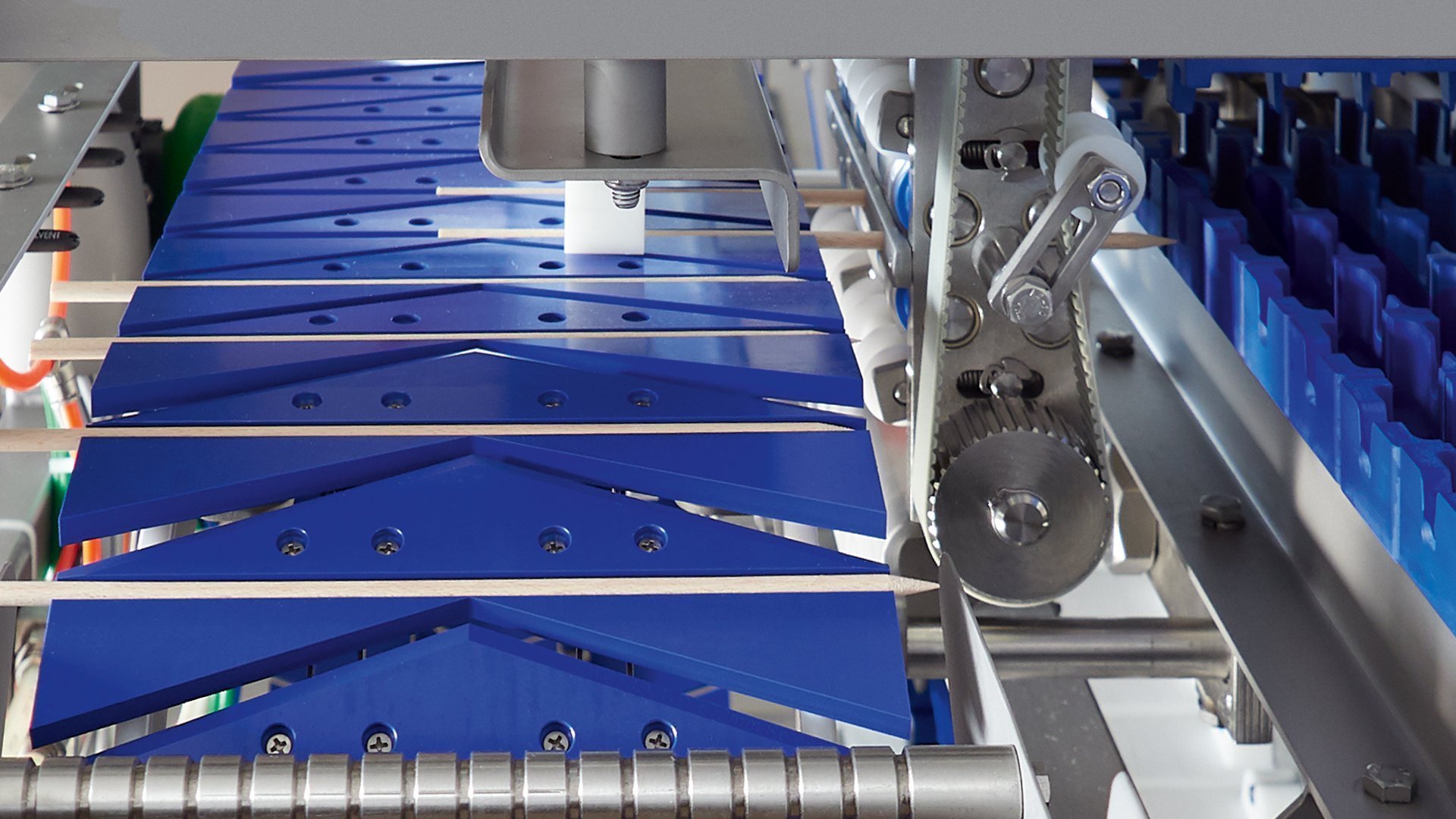

Skewer System 7200

Skewer System 7200 is designed to provide maximum reliability, flexibility, and scalability, ensuring you always have ample skewer capacity. It is a computer controlled system, serving as the successor to the highly successful Skewer System 4080.

Why choose the Skewer System 7200?

- Computer-controlled system accommodates a diverse range of products, like meat, cheese, fish, shrimp, sausages, etc.

- Individual cassettes available for customer specific products.

- Guarantees optimal efficiency, capable of producing an impressive range from 12 to 120 finished skewers per minute.

- Quick product changes and easy cleaning.

- Modular extensions available like automated loading and lean in place module.

- Guaranteed output of at least 95%

Skewer System 4080

Whether it's meat, poultry, minced meat, cheese, fish, or vegetables, the Skewer System 4080 helps you produce up to 4080 handmade-looking skewers per hour, requiring only 2-8 employees. The system's flexibility shows in its modular design, allowing seamless upgrades to a production line with features like automated loading, unloading, or the Clean in Place Module.

Why choose the Skewer System 4080?

Skewer System 2040

Whether it's chicken, pork, beef, fish, vegetables, fruit, cheese or new meat, the Skewer System 2040 helps you produce up to 2040 handmade-looking skewers per hour, requiring only 2-8 employees. This system comes with an add-on feature including MIVEG Multi-Cassette, allowing you to produce two different grill skewers at once.

Why choose the Skewer System 2040?

- Includes MIVEG Multi-Cassette

- Adjustable production rate upto 34 skewers per minute

- Accommodates round and flat skewers.

- Suitable for meat, cheese, vegetables, fruit, fish, and sausages.

- Tailor-made product moulds to meet customer specifications.

- Quick product changes and easy cleaning.

- Guaranteed output of at least 95%.

How can you benefit from our experience?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.