Synchropack Flow-wrapper Range

We collaborate closely with our partner, Synchropack, to provide high-quality flow-wrapper solutions to our clients. Our flow wrappers offer an ideal solution to enhance your company's production efficiency while simultaneously reducing costs. Featuring customizable options and dependable performance, each of our flow wrapping machines ensures meticulous and consistent packaging of your products. Specifically designed for versatility, our Horizontal flow pack wrapping machines excel in packaging various product types, whether in primary or secondary wrapping packages (multipack). A standout feature of Synchropack's flow pack wrappers lies in their project-specific customisation - you get a customised automation to manage your processed product to stacks, piles and rows that feed into the flow-wrapper. Upgrade your packaging process, boost productivity, and diversify your output with our reliable and adaptable flow packing machines capable of handling a range of products and packaging styles.

Download BrochureRAF (Roll Automatic Feeder) - Bread sticks

POS (Product Orientation Systems) - Chocolates

POS (Product Orientation Systems) + MSS (Medium Speed Synchronizer) - Bakery Pack

Coated Rice Biscuits - Complete wrapping line with buffer

SAF (Slug Automatic Feeder) - Biscuits

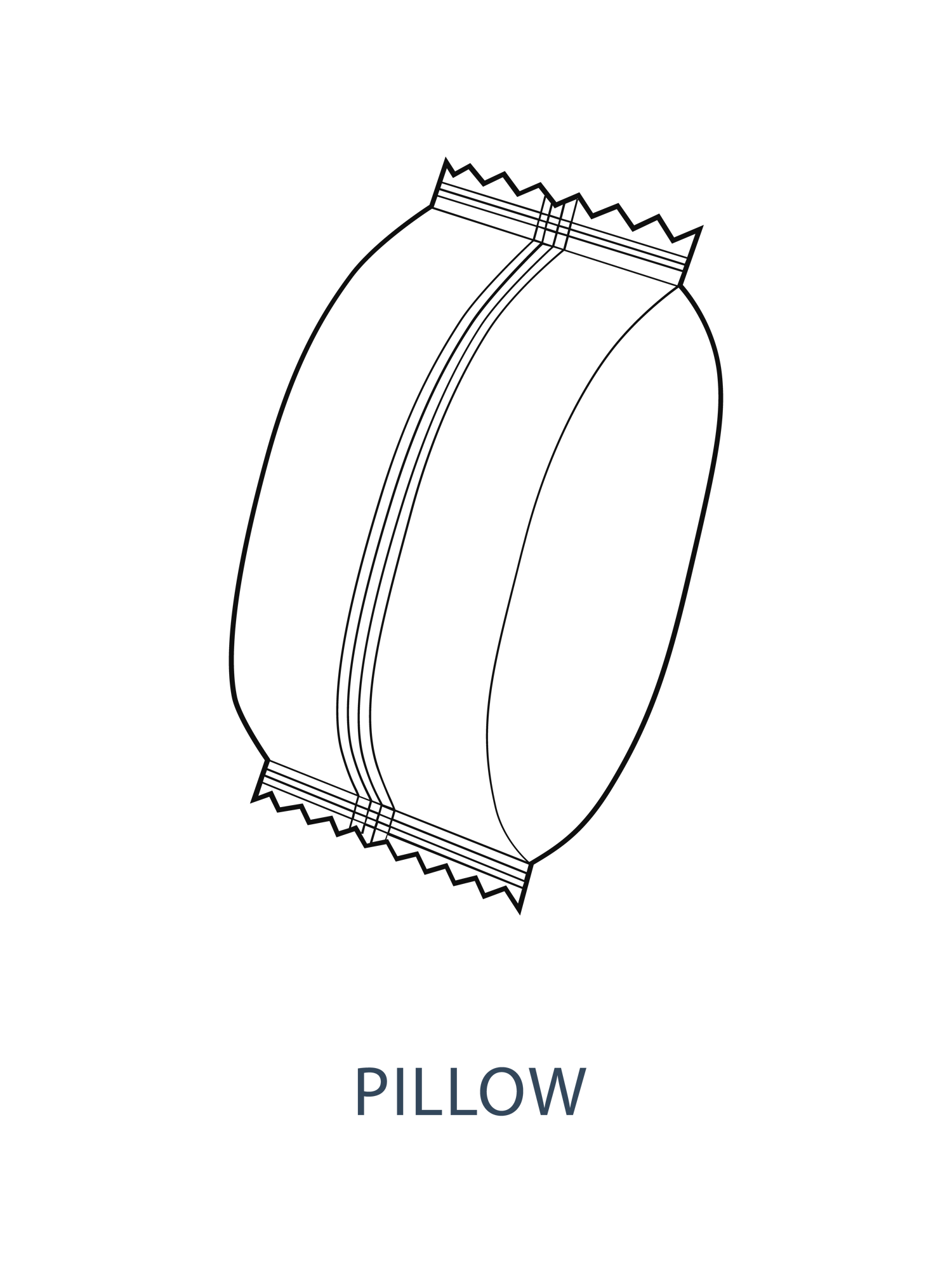

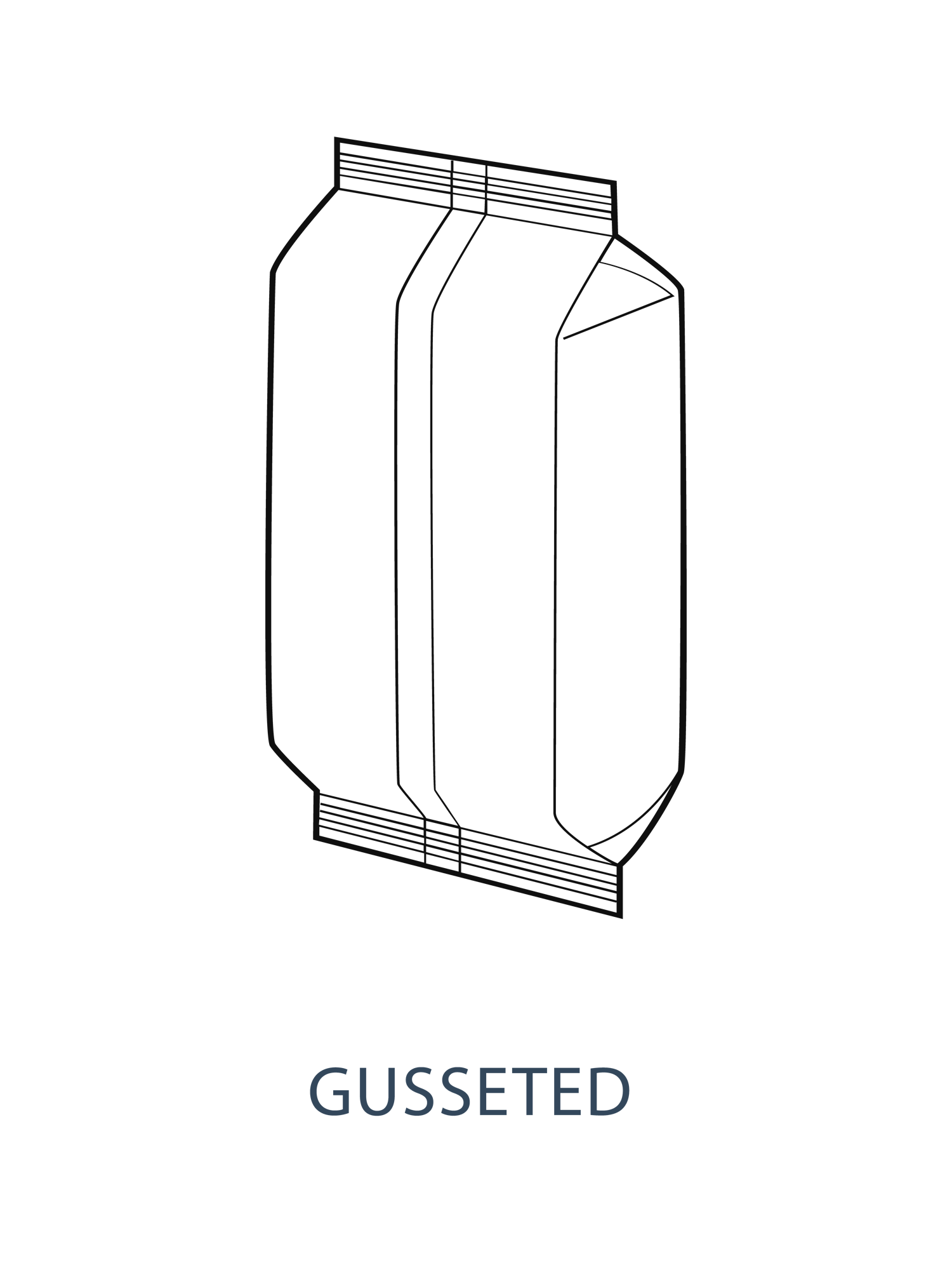

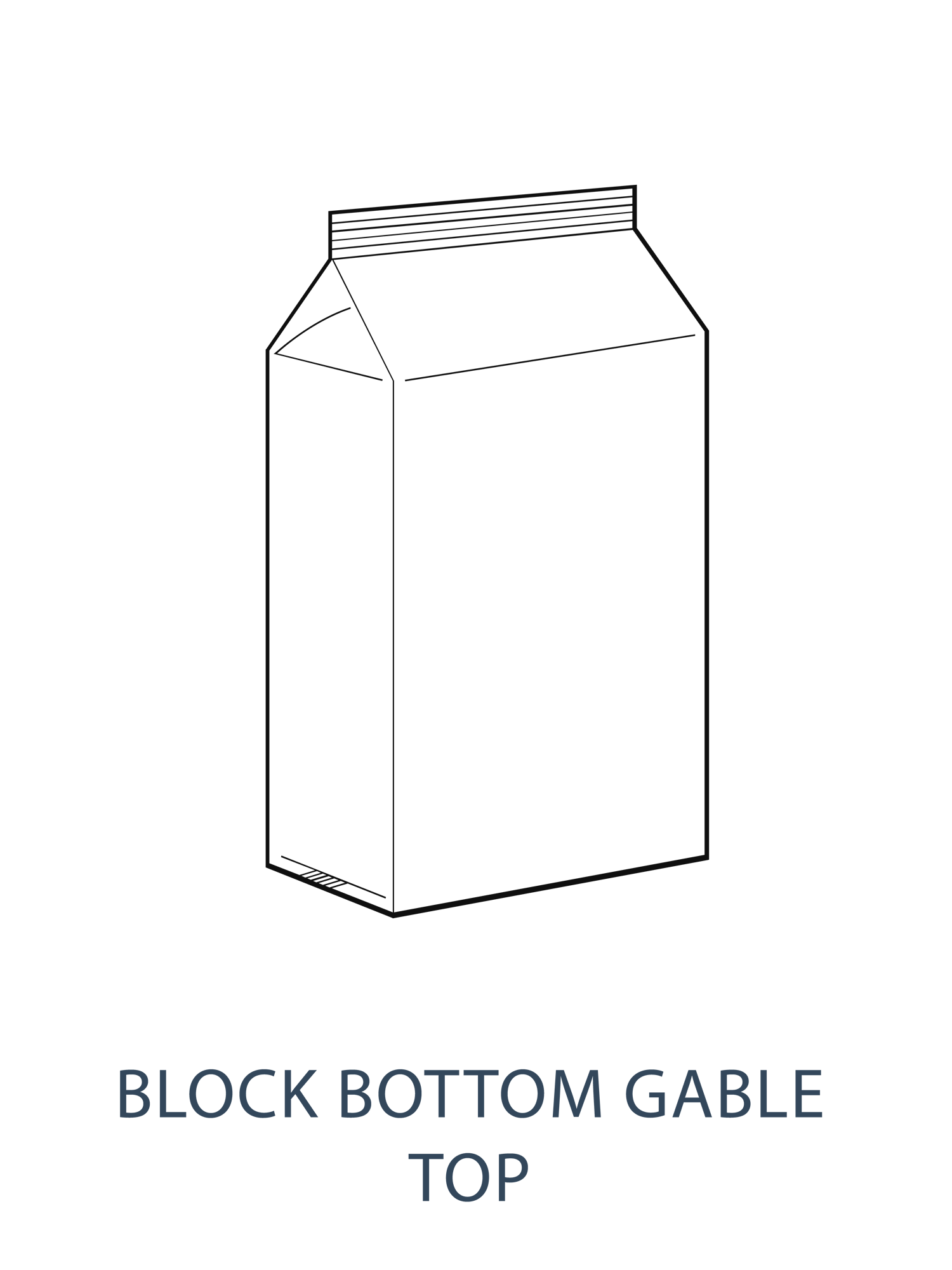

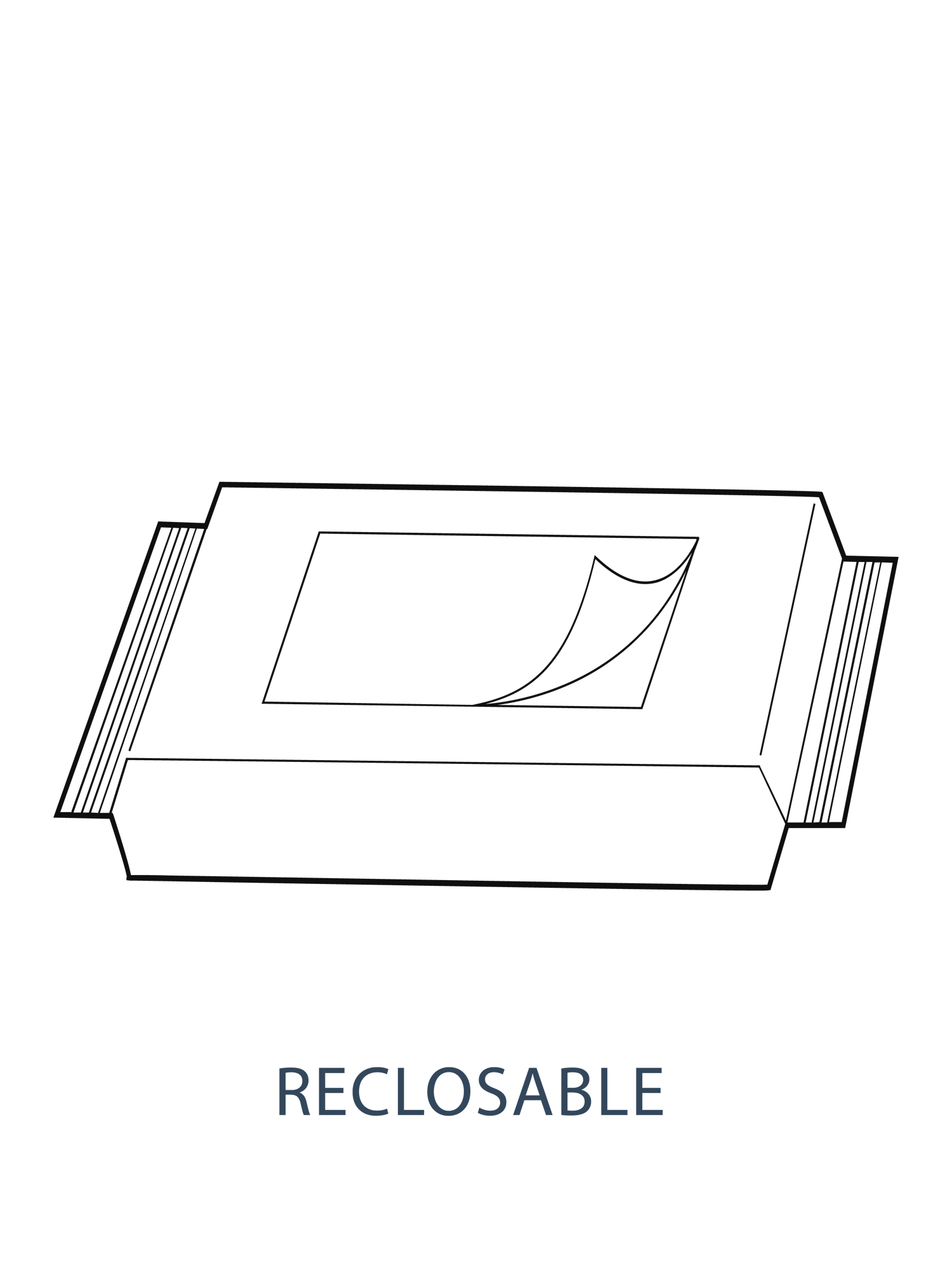

Types of Pack Styles Available

The 9-Series

The PACK 90 (top film reel holder), is an electronic flowpack machine that excels in wrapping regular products across low or medium production runs, offering options for both semi-automatic and automatic feeding while accommodating multiple format changes. Its cantilever design, modular construction, high flexibility & performance, ease of operation, swift changeover, low maintenance costs, and comprehensive electronic control, stand out as the primary attributes of this model. Leveraging a shared platform, this machine has been diversified into various configurations, complemented by a wide array of accessories, enabling the Pack 900 to seamlessly adapt to diverse product types and meet the rigorous demands of various production environments.

The PACK 90 (top film reel holder), is an electronic flowpack machine that excels in wrapping regular products across low or medium production runs, offering options for both semi-automatic and automatic feeding while accommodating multiple format changes. Its cantilever design, modular construction, high flexibility & performance, ease of operation, swift changeover, low maintenance costs, and comprehensive electronic control, stand out as the primary attributes of this model. Leveraging a shared platform, this machine has been diversified into various configurations, complemented by a wide array of accessories, enabling the Pack 900 to seamlessly adapt to diverse product types and meet the rigorous demands of various production environments.

|

Pack 90 Automatic Flow-Wrapper |

|||

|

Machine Size |

Small |

Medium |

Large |

|

Max Film Width |

300 |

500 |

700 |

|

Product Length Min/Max |

20 - 160 |

80 - 450 |

110 - 550 |

|

Max ppm |

300 |

200 |

100 |

|

Jaw Width |

100 |

200 |

300 |

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Universal Forming Box: Upper universal forming tunnel, adaptable in height, width, angle, and position to suit various product sizes and shapes for wrapping.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange

- Outfeed Conveyor: Equipped with independent variable speed motorization, adjustable to match wrapping speed for the wrapped product.

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

The PACK 900 (top film reel holder), is an electronic flowpack machine that excels in wrapping products across regular, medium, and high production volumes, offering options for both semi-automatic and automatic feeding while accommodating multiple format changes. Its cantilever design, modular construction, high flexibility & performance, ease of operation, swift changeover, low maintenance costs, and comprehensive electronic control, stand out as the primary attributes of this model. Leveraging a shared platform, this machine has been diversified into various configurations, complemented by a wide array of accessories, enabling the Pack 900 to seamlessly adapt to diverse product types and meet the rigorous demands of various production environments.

The PACK 900 (top film reel holder), is an electronic flowpack machine that excels in wrapping products across regular, medium, and high production volumes, offering options for both semi-automatic and automatic feeding while accommodating multiple format changes. Its cantilever design, modular construction, high flexibility & performance, ease of operation, swift changeover, low maintenance costs, and comprehensive electronic control, stand out as the primary attributes of this model. Leveraging a shared platform, this machine has been diversified into various configurations, complemented by a wide array of accessories, enabling the Pack 900 to seamlessly adapt to diverse product types and meet the rigorous demands of various production environments.

|

Pack 900 Automatic Flow-Wrapper |

|||

|

Machine Size |

Small |

Medium |

Large |

|

Max Film Width |

300 |

500 |

700 |

|

Product Length Min/Max |

20 - 160 |

80 - 450 |

110 - 550 |

|

Max ppm |

600 |

400 |

200 |

|

Jaw Width |

100 |

200 |

300 |

-

Pallet conveyor: Belt with easily adjustable pusher paddles for tool-free distance variation.

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Universal Forming Box: Upper universal forming tunnel, adaptable in height, width, angle, and position to suit various product sizes and shapes for wrapping.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange.

- Longitudinal Welding Unit: Easily removable for maintenance and cleaning, requiring just loosening two screws and an electric-pneumatic connector. It offers the convenience of quick replacement with a spare module.

-

Cutting and Welding Unit: Versatile rotary cutter-welder unit, offered in various diameters, jaw configurations, widths, and teeth options to match the dimensions of diverse products and the type of film selected for wrapping.

- Outfeed Conveyor with Ejection: Equipped with an independent variable speed motorisation, this conveyor adjusts to wrapping speed, featuring a detection and rejection system for empty and double bags.

- Transmission: Transmission cabinet

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

The Pack 9000 (top film reel holder), is an electronic flowpack machine that is suitable for both standard products and high-volume production, offering automated feeds and seamless transitions between multiple formats. Its key attributes include a robust design, modular construction, flexibility, and high performance. With user-friendly features facilitating easy format changes and total electronic control, this wrapping model requires minimal maintenance. The common platform of the Pack 9000 has spawned various configurations, coupled with a diverse array of accessories, enabling it to seamlessly accommodate a wide range of products and meet the rigorous demands of diverse production environments.

The Pack 9000 (top film reel holder), is an electronic flowpack machine that is suitable for both standard products and high-volume production, offering automated feeds and seamless transitions between multiple formats. Its key attributes include a robust design, modular construction, flexibility, and high performance. With user-friendly features facilitating easy format changes and total electronic control, this wrapping model requires minimal maintenance. The common platform of the Pack 9000 has spawned various configurations, coupled with a diverse array of accessories, enabling it to seamlessly accommodate a wide range of products and meet the rigorous demands of diverse production environments.

|

Pack 9000 Automatic Flow-Wrapper |

||

|

Machine Size |

Small |

Medium |

|

Max Film Width |

300 |

500 |

|

Product Length Min/Max |

20 - 160 |

80 - 220 |

|

Max ppm |

800 |

600 |

|

Jaw Width |

100 |

200 |

-

Pallet conveyor: Belt with easily adjustable pusher paddles for tool-free distance variation.

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Fixed Forming Box: Specifically designed for the height and width of the product to be wrapped.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange.

- Longitudinal Welding Unit: Easily removable for maintenance and cleaning, requiring just loosening two screws and an electric-pneumatic connector. It offers the convenience of quick replacement with a spare module.

-

Cutting and Welding Unit: Versatile rotary cutter-welder unit, offered in various diameters, jaw configurations, widths, and teeth options to match the dimensions of diverse products and the type of film selected for wrapping.

- Outfeed Conveyor with Ejection: Equipped with an independent variable speed motorisation, this conveyor adjusts to wrapping speed, featuring a detection and rejection system for empty and double bags.

- Transmission: Transmission cabinet

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

The 6-Series

The Pack 60 (bottom film reel holder), is an electronic flowpack machine designed for wrapping irregular or fragile products during low or medium production runs. It offers versatility with options for manual, semi-automatic, or automatic feeding, along with the capability for multiple format changes. Its cantilever design, modular construction, high flexibility and performance, coupled with easy operation and changeover, make it a standout model in wrapping machines. Additionally, it boasts low maintenance costs and full electronic control as its primary features. This adaptable model has various configurations developed to accommodate different products and meet the stringent requirements of diverse production environments, thanks to its wide range of available accessories.

|

Pack 60 Automatic Flow-Wrapper |

|||

|

Machine Size |

Small |

Medium |

Large |

|

Max Film Width |

300 |

500 |

700 |

|

Product Length Min/Max |

20 - 160 |

80 - 450 |

110 - 550 |

|

Max ppm |

300 |

200 |

100 |

|

Jaw Width |

100 |

200 |

300 |

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Universal Forming Box: Upper universal forming tunnel, adaptable in height, width, angle, and position to suit various product sizes and shapes for wrapping.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange

- Outfeed Conveyor: Equipped with independent variable speed motorization, adjustable to match wrapping speed for the wrapped product.

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

The PACK 600 (bottom film reel holder) is the electronic flowpack machine suitable for wrapping irregular or delicate products across medium to high production volumes. It offers the versatility of both semi-automatic and automatic feeding, accommodating multiple format changes seamlessly. Its cantilever design, modular construction, exceptional flexibility, high-performance capability, user-friendly operation and transition, minimal maintenance costs, and complete electronic control constitute the primary attributes of this wrapping machine model. The model has various configurations, complemented by a diverse range of available accessories, enabling the Pack 600 to adapt effortlessly to diverse product types and meet stringent requirements across diverse production settings.

|

Pack 600 Automatic Flow-Wrapper |

|||

|

Machine Size |

Small |

Medium |

Large |

|

Max Film Width |

300 |

500 |

700 |

|

Product Length Min/Max |

20 - 160 |

80 - 450 |

110 - 550 |

|

Max ppm |

600 |

400 |

200 |

|

Jaw Width |

100 |

200 |

300 |

-

Pallet conveyor: Belt with easily adjustable pusher paddles for tool-free distance variation.

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Universal Forming Box: Upper universal forming tunnel, adaptable in height, width, angle, and position to suit various product sizes and shapes for wrapping.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange.

- Longitudinal Welding Unit: Easily removable for maintenance and cleaning, requiring just loosening two screws and an electric-pneumatic connector. It offers the convenience of quick replacement with a spare module.

-

Cutting and Welding Unit: Versatile rotary cutter-welder unit, offered in various diameters, jaw configurations, widths, and teeth options to match the dimensions of diverse products and the type of film selected for wrapping.

- Outfeed Conveyor with Ejection: Equipped with an independent variable speed motorisation, this conveyor adjusts to wrapping speed, featuring a detection and rejection system for empty and double bags.

- Transmission: Transmission cabinet

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

The 3-Series

The PACK 30 (top and bottom film reel holder), is an electronic flowpack machine suitable for compact products with minimal height. It is designed for low to medium production volumes, accommodating manual or semi-automatic feeding and facilitating multiple format changes. The machine boasts a cantilever design, modular construction, high flexibility and performance, ensuring ease of operation and changeover. With low maintenance costs and complete electronic control, this wrapping machine model offers a range of features. Its versatile common platform has been utilized to create various configurations, coupled with an array of accessories, allowing the Pack 30 to adapt seamlessly to diverse products and meet the most stringent requirements in various production settings.

The PACK 30 (top and bottom film reel holder), is an electronic flowpack machine suitable for compact products with minimal height. It is designed for low to medium production volumes, accommodating manual or semi-automatic feeding and facilitating multiple format changes. The machine boasts a cantilever design, modular construction, high flexibility and performance, ensuring ease of operation and changeover. With low maintenance costs and complete electronic control, this wrapping machine model offers a range of features. Its versatile common platform has been utilized to create various configurations, coupled with an array of accessories, allowing the Pack 30 to adapt seamlessly to diverse products and meet the most stringent requirements in various production settings.

|

Pack 30 Automatic Flow-Wrapper |

|||

|

Machine Size |

Small |

Medium |

Large |

|

Max Film Width |

150 |

250 |

350 |

|

Product Length Min/Max |

On application |

On application |

On application |

|

Max ppm |

300 |

200 |

100 |

|

Jaw Width |

100 |

200 |

300 |

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange

- Outfeed Conveyor: Equipped with independent variable speed motorization, adjustable to match wrapping speed for the wrapped product.

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

The PACK 300 (top and bottom film reel holder), stands out as an electronic flowpack machine suitable for small-height products, for medium and high-production runs, and manual, semi-automatic, or automatic feeding, with multiple format changes. Noteworthy features of this model include its cantilever design, modular construction, high flexibility and performance. Operating with ease and facilitating quick changeovers, the machine boasts low maintenance costs and full electronic control. The platform has multiple configurations, complemented by a diverse range of accessories, enabling the Pack 300 to seamlessly adapt to a wide array of products and meet the most stringent requirements in various production.

The PACK 300 (top and bottom film reel holder), stands out as an electronic flowpack machine suitable for small-height products, for medium and high-production runs, and manual, semi-automatic, or automatic feeding, with multiple format changes. Noteworthy features of this model include its cantilever design, modular construction, high flexibility and performance. Operating with ease and facilitating quick changeovers, the machine boasts low maintenance costs and full electronic control. The platform has multiple configurations, complemented by a diverse range of accessories, enabling the Pack 300 to seamlessly adapt to a wide array of products and meet the most stringent requirements in various production.

|

Pack 300 Automatic Flow-Wrapper |

|||

|

Machine Size |

Small |

Medium |

Large |

|

Max Film Width |

150 |

250 |

350 |

|

Product Length Min/Max |

On application |

On application |

On application |

|

Max ppm |

600 |

400 |

200 |

|

Jaw Width |

100 |

200 |

300 |

-

Pallet conveyor: Belt with easily adjustable pusher paddles for tool-free distance variation.

- Reel Holder: Pneumatically expands to securely grip film reels, allowing axial adjustment on the operator's side even during machine operation.

- Universal Forming Box: Upper universal forming tunnel, adaptable in height, width, angle, and position to suit various product sizes and shapes for wrapping.

- Longitudinal Sealing Unit: Modular design, comprising cold film-dragging wheels, two sets of heated sealing wheels, and conical wheels for bending the sealing flange.

- Longitudinal Welding Unit: Easily removable for maintenance and cleaning, requiring just loosening two screws and an electric-pneumatic connector. It offers the convenience of quick replacement with a spare module.

-

Cutting and Welding Unit: Versatile rotary cutter-welder unit, offered in various diameters, jaw configurations, widths, and teeth options to match the dimensions of diverse products and the type of film selected for wrapping.

- Outfeed Conveyor with Ejection: Equipped with an independent variable speed motorisation, this conveyor adjusts to wrapping speed, featuring a detection and rejection system for empty and double bags.

- Transmission: Transmission cabinet

- 10.4″ color touch screen: Intuitively interact with the machine, displaying all operating parameters, warnings, alarms, etc.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.