Label and Code Inspection

Antares Vision Group’s label and code inspection solutions are tailored to meet the demands of the food industry. Our advanced systems employ state-of-the-art cameras to inspect 100% of production, ensuring brand protection and minimising returns and associated costs. These inspections cover label quality, legibility, and the inclusion of essential data such as nutritional information, barcodes, and expiry dates, as well as ensure full compliance and accurate reading of 2D codes (Barcode, Datamatrix, QR-code) and alphanumeric codes (lot number, expiration date), whether printed on the container, cap, or label, using sophisticated vision systems. We can build our machines fully to retail specification.

Label Inspection

For Horizontal Products

The label inspection solution for horizontal packages is equipped with a dedicated camera to inspect labels and codes positioned above, below, or on both sides of the package. This system ensures comprehensive inspection coverage, enhancing the accuracy of label verification.

Additionally, the label inspection system provides real-time data updates, immediately detecting and rejecting defective products to prevent them from reaching the shelves. The IE 700 Series helps reduce costs associated with scraps, recalls, and manual inspection labour, ensuring that your products are safe and high-quality when they reach the end customer.

Models:

- IE 700 with top-down camera

- IE 700 with down-top camera

- IE 700 with double camera

Inspections:

For Cylindrical Vertical Products

The IE4000 PLUS is an advanced version of the IE4000, widely used by major food and beverage manufacturers. It inspects various label types, including front/back, wraparound, sleeve, and collar labels, on non-oriented round-based containers like jars, cans, and bottles.

Equipped with four cameras, the system uses AI to create a 3D model of each product, correcting surface distortions for precise 360° inspection. It checks label presence, positioning, and integrity, reads codes with OCR technology, and offers an emboss detection option. The compact design integrates the HMI and Vision PC, reducing operator intervention and simplifying setup and format changes.

Inspections:

- Label presence, matching, positioning (vertical, horizontal, rotation), quality/integrity, double applications

- Axiality/Alignment between different elements

- Emboss detection and analysis of the alignment with labels (optional)

- Absence of defects in the sealing area of sleeve labels

- Capsule presence, correct positioning, type and color matching

- Alignment between capsule and neck label

- Presence of liquid

- Presence and integrity of code (lot, expiration date, etc.)

- Reading of 1D and 2D codes (Barcode, Datamatrix, QR-Code, etc.)

For Vertical Products

The label inspection system for oriented products is designed to verify label quality by ensuring correct positioning, format accuracy, integrity, and code verification or reading, even on opaque and partially transparent labels. The system’s configuration can be tailored to the specific type of inspection, label characteristics, and the level of precision required to meet the customer’s unique needs.

Inspections:

For Any Type Of Container - IE6000

The IE6000 is a versatile solution for inspecting various types of labels, including front/back, wraparound, sleeve, collar, opaque, and partially transparent labels on containers of any shape—round, square, rectangular, or oval. It efficiently handles both oriented and non-oriented containers, allowing for seamless inspection of diverse product batches on the same line.

The system uses advanced cameras to adapt to the specific characteristics of each product. For cylindrical containers, four cameras capture multiple images, and artificial intelligence reconstructs a 360° 3D model for precise label inspection. For non-cylindrical containers, six cameras are employed to cover all sides, ensuring comprehensive label verification. The IE6000 monitors label presence, positioning, and integrity while reading codes through OCR technology and detecting embosses. Compact and easy to operate, it minimises operator intervention and ensures optimal performance with real-time alerts to prevent waste.

Inspections:

- Label presence, matching, positioning (vertical, horizontal, rotation), quality/integrity, double applications

- Axiality/Alignment between different elements

- Emboss detection and analysis of the alignment with labels (optional)

- Absence of defects in the sealing area of sleeve labels

- Capsule presence, correct positioning, type and color matching

- Alignment between capsule and neck label

- Presence of liquid

- Presence and integrity of code (lot, expiration date, etc.)

- Reading of 1D and 2D codes (Barcode, Datamatrix, QR-Code, etc.)

Code Inspection

Code Inspection - IC700

The IC 700-IoT is a comprehensive code inspection system designed to ensure accurate reading and compliance of 2D codes (such as Barcode, Datamatrix, QR-code) and alphanumeric codes (like lot number and expiration date). It inspects codes printed on the container body, cap, or label using advanced vision systems.

Inspections:

- 2D and 3D code reading

- OCR/OCV codes reading

- Presence check

- Matching check

- Positioning check

- Integrity Check

- Language check

- Reading of barcode, Datamatrix or QR-Code

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

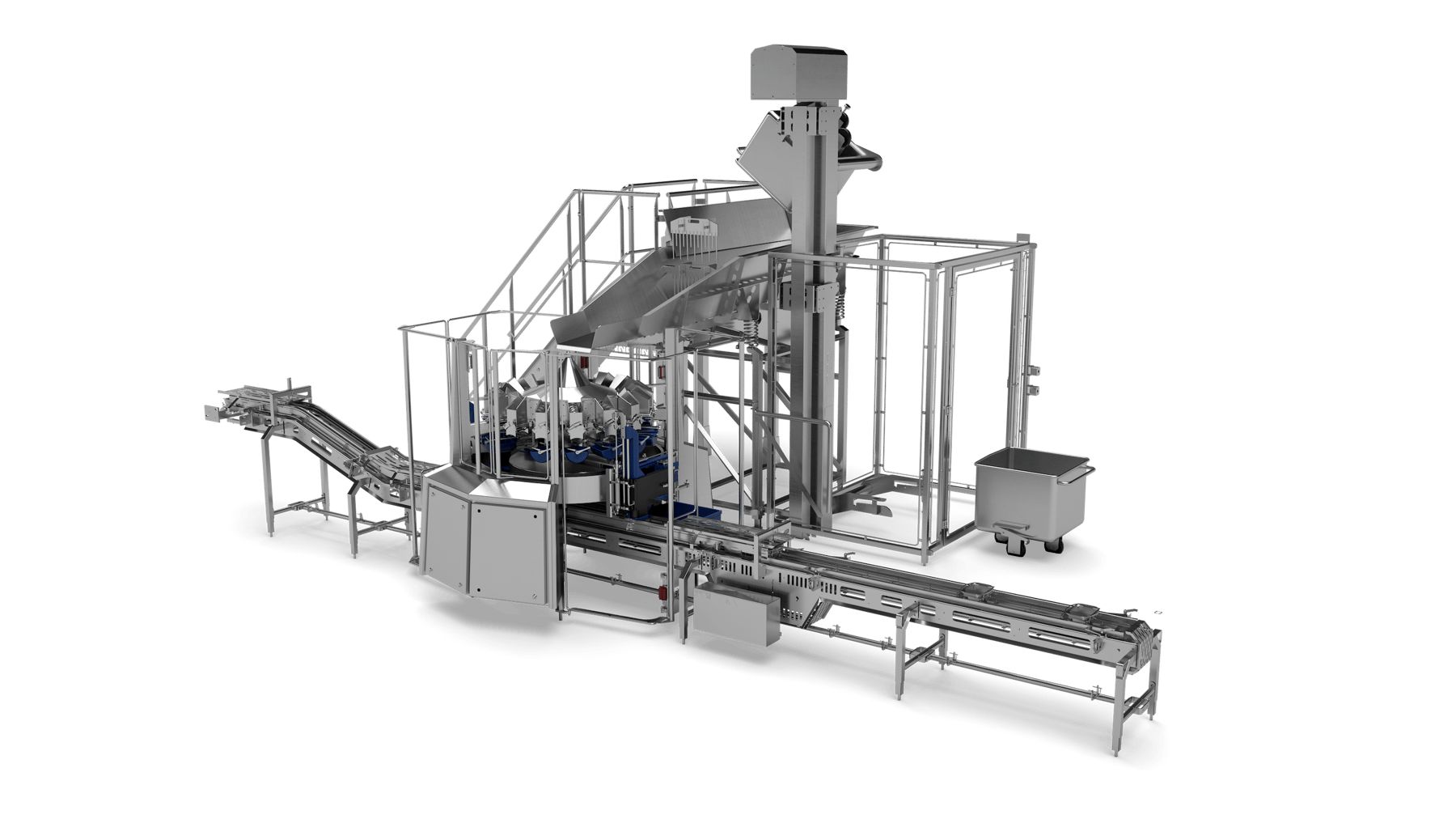

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.