Cabinplant Blanchers and Coolers Equipment Range

The delicate nature of the majority of produce and seafood necessitate the use of gentle processing equipment to preserve their essential nutritional properties and delightful taste. Collaborating with our partner, Cabinplant, we provide top-tier blanchers and coolers designed to guarantee the retention of your product's vital nutritional qualities, as well as it's consistency and appearance which are equally important.

Blanchers and Coolers

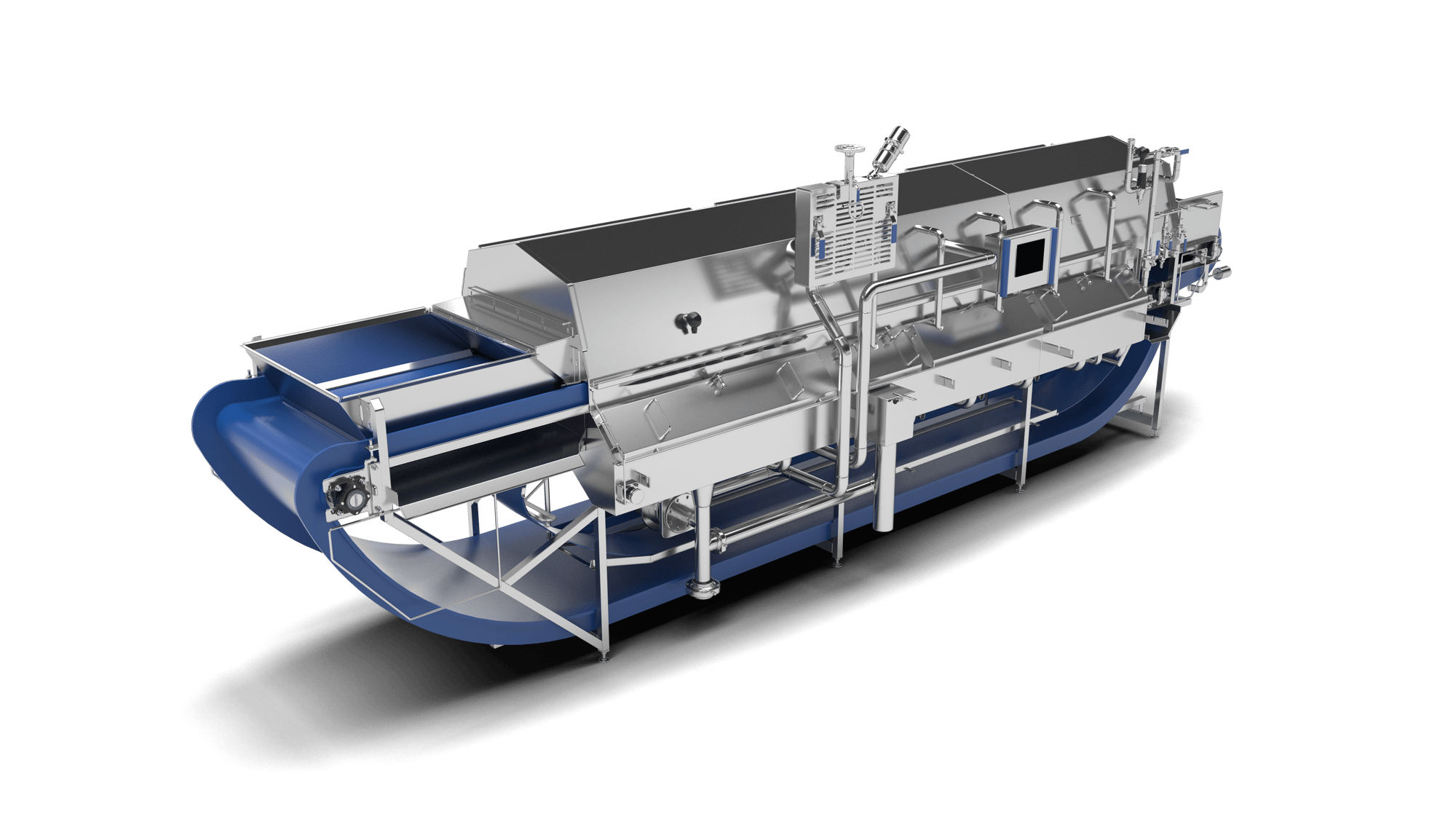

Belt Cookers SCWC

Gentle and Adaptable

The Cabinplant belt cooker is specifically designed for continuous cooking and cooling of various products such as vegetables, fish, or others, and can be customized to fulfill specific needs. The primary benefit of this cooker lies in its ability to enhance yield during the cooking phase, leading to a swift return on investment.

Functionality:

-

Cooking is by water or steam.

-

All types are integrated cookers/coolers, some integrate product pre-heating with up to 40% heat recovery.

-

Heating of cooking water is either by direct steam or by means of a heat exchanger.

-

Cooling is either by water/chilled water, air or a combination of both.

IBC Blancher with Forced Steam

Cabinplant’s IBC blancher with forced stream incorporates a sophisticated integrated cooling segment equipped with a cutting-edge counterflow cooling mechanism. This advancement in technology significantly reduces water usage during the cooling phase. Additionally, the blancher facilitates efficient pre-heating, resulting in notable reductions in steam consumption—up to 50-60% less compared to conventional blanchers lacking pre-heating functions. Offering the flexibility to adjust product discharge temperatures according to specific requirements, it enables maintaining an ideal temperature of approximately 12°C when utilizing 1°C cooling water.

Functionality:

BAC Blancher

The Cabinplant BAC blancher/cooler is distinguished as the most economical choice for water conservation during the cooling process. This efficiency is attained through a cooling system predominantly powered by either evaporation alone or a blend of evaporation and the application of chilled water. The selection between these methods is contingent on the targeted product discharge temperature.

Advantages:

-

Low risk of product contamination even after long operating hours

-

Integrated blancher and cooler

-

No product damage

-

High yield

-

Uniform blanching

-

High degree of flexibility with regard to blanching time and temperature

-

Evaporative air-cooling section incl. fan

-

Additional lowering of product temperature by means of recirculated chilled water, option

-

Customer-adapted design

-

Hygienic design makes cleaning easy

-

Capacity from 2 to 30 t/h

BC Blancher

The BC blancher/cooler is a specially designed, compact blancher customized for smaller production capacities, spanning from 1 to 9 tons per hour. Furthermore, the incorporation of cooling water is precisely regulated according to the product volume using a thermostatic water valve.

Functionality:

-

An infeed section where the product is introduced and uniformly distributed onto the blanching belt.

-

A dedicated blanching section responsible for heating the product. This is accomplished by gently spraying it with recirculated water, which is heated using precisely controlled injected live steam regulated by a modulating steam control valve.

-

A dedicated cooling section where cooling water is actively pumped to efficiently cool the product. This process is executed in a counterflow manner relative to the product’s path, ensuring optimal temperature reduction.

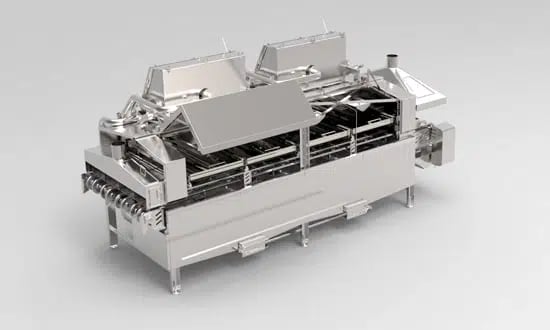

MTS Batch Cooker

Cabinplant's MTS Batch Cooker combines tray cooking and cooling of shrimps into a single process, enabling in-line production of warm water HOSO shrimps using block-frozen product. Each step of the entire line utilizes water distribution from above, gently cascading onto the product, ensuring consistent and gentle treatment throughout production. Moreover, the complete line provides adjustable treatment times at each process step.

Functionality:

-

Defrosting

-

Metabisulphite treatment

-

Cooking

-

Cooling

-

Coloring

-

Brine freezing

Rice Cooker

Cabinplant rice cookers ensure perfect cooking outcomes through specialised piping systems that evenly distribute cooking and cooling water onto the product. These industrial rice cookers offer significant benefits, including low water consumption and high cooking yield.

Rice is conveyed on a belt and treated with a large volume of recirculated steam-heated water before entering the cooling section, where it's chilled using a combination of air and water. This continuous process on the same belt minimises bacteriological risks as the belt undergoes continuous heat treatment.

Designed for 2 tons per hour of finished cooked and chilled rice, this rice cooker/cooler features a belt width of 2,000 mm and a cooking time of approximately 16 minutes. It achieves a weight gain of approximately 235%. Pre-soaking the rice can again increase the weight gain to approximately 265%.

Chillers

Baudelot Chiller

The Cabinplant water chiller is of the Baudelot (falling film) type. Here, water is evenly distributed from a central overhead trough onto both sides of vertical stainless steel plates. This arrangement ensures a thin, uniform flow of water over the computer-engineered outer surface of the plates, maximizing the outside film coefficient.

The unit consists of:

-

Rotating filter (optional) or parabolic screen as on picture

-

Distribution

-

Computer-designed cooling plates

-

Collection/accumulation tank

-

Recirculation pumps

-

Fresh water connection with automatic level control

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.