VDL UVA Bagmaker Range

Our partner in VFFS packaging, VDL, provides versatility and dependability to accommodate various bag styles with their machines. Our consultants, equipped with practical application knowledge, collaborate with you to deliver optimal machinery and additional equipment seamlessly integrated into your production line. Bag styles encompass pillow, block bottom, corner seal, doy pack, and more.

Types of Bag Styles Available

The Continuous Motion Machines

Continuous VFFS machines move film while filling and sealing, maximising speed and efficiency. Ideal for high-volume packaging like snacks and pet food, they minimise downtime and increase throughput.

UVA Dynamic Hydro

- Technology: Continuous Motion

- Frame: Closed, stainless steel frame

- Jaw width (mm): 320 / 400

- Machine dimensions (w/d/h in mm): 1,500 / 3,256 / 1,655

- Machine weight (approx.): 840 kg

- Power supply: 10 / 12.5 kVA

- PackML integration: Yes

- Max. seal pressure: 6 kN

- Compressed air requirement: 6 bar

- Mechanical bag output: 150 bags per minute

- Max. film roll diameter (mm): 550

- Max film width (mm): 850

- Min. bag size (w/d/h in mm): 50 x 30 x 60

- Max. bag size (w/d/h in mm): 400 x 150 x 600

- IP standard: IP66

- Sealing methods: Heat Seal (optional ceramic seal)

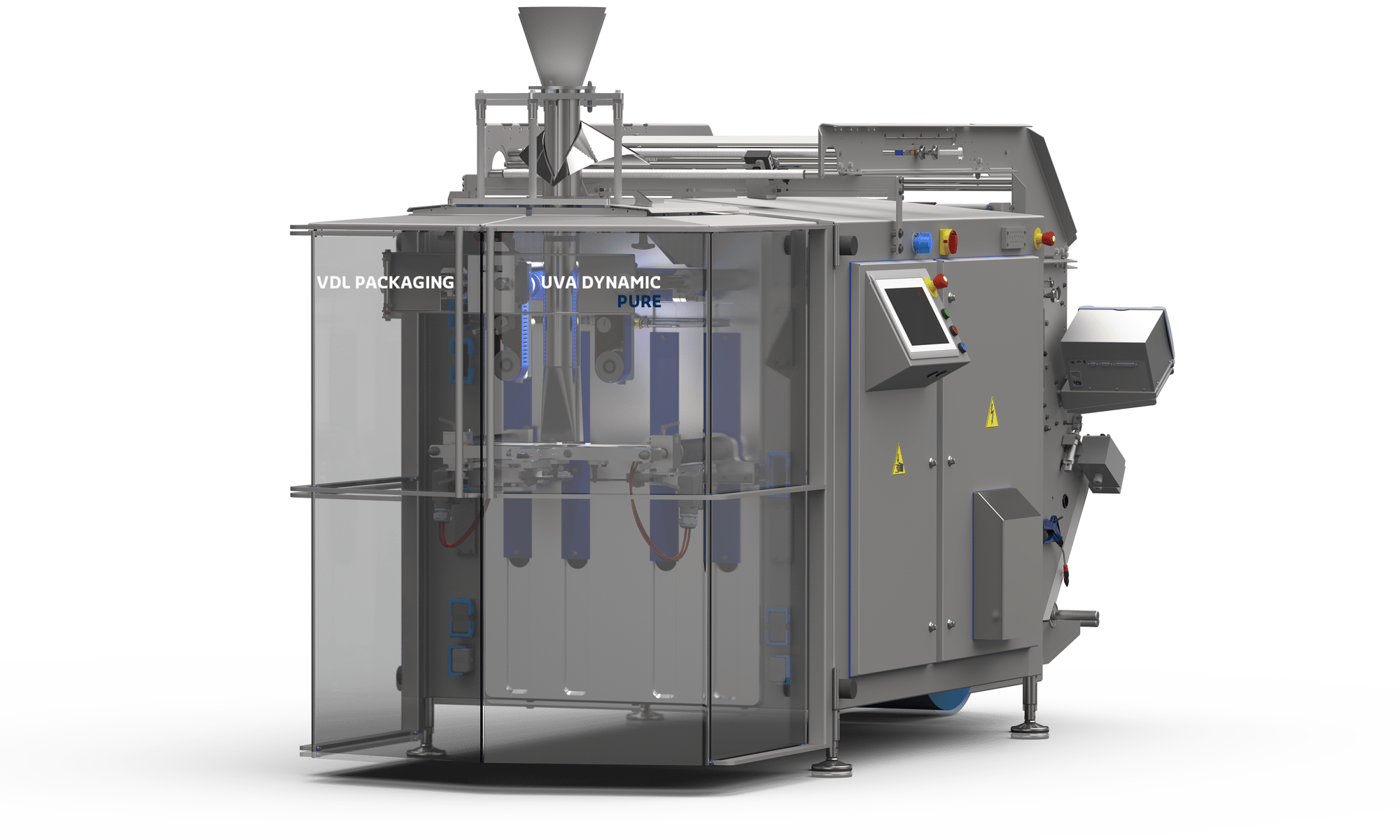

UVA Dynamic Pure

- Technology: Continuous Motion

- Frame: Closed, stainless steel frame

- Jaw width (mm): 320 / 400

- Machine dimensions (w/d/h in mm): 1,500 / 3,256 / 1,655

- Machine weight (approx.): 840 kg

- Power supply: 10 / 12.5 kVA

- PackML integration: Yes

- Max. seal pressure: 6 kN

- Compressed air requirement: 6 bar

- Mechanical bag output: 150 bags per minute

- Max. film roll diameter (mm): 550

- Max film width (mm): 850

- Min. bag size (w/d/h in mm): 50 x 30 x 60

- Max. bag size (w/d/h in mm): 400 x 150 x 600

- IP standard: IP55

- Sealing methods: Heat Seal (optional ceramic seal)

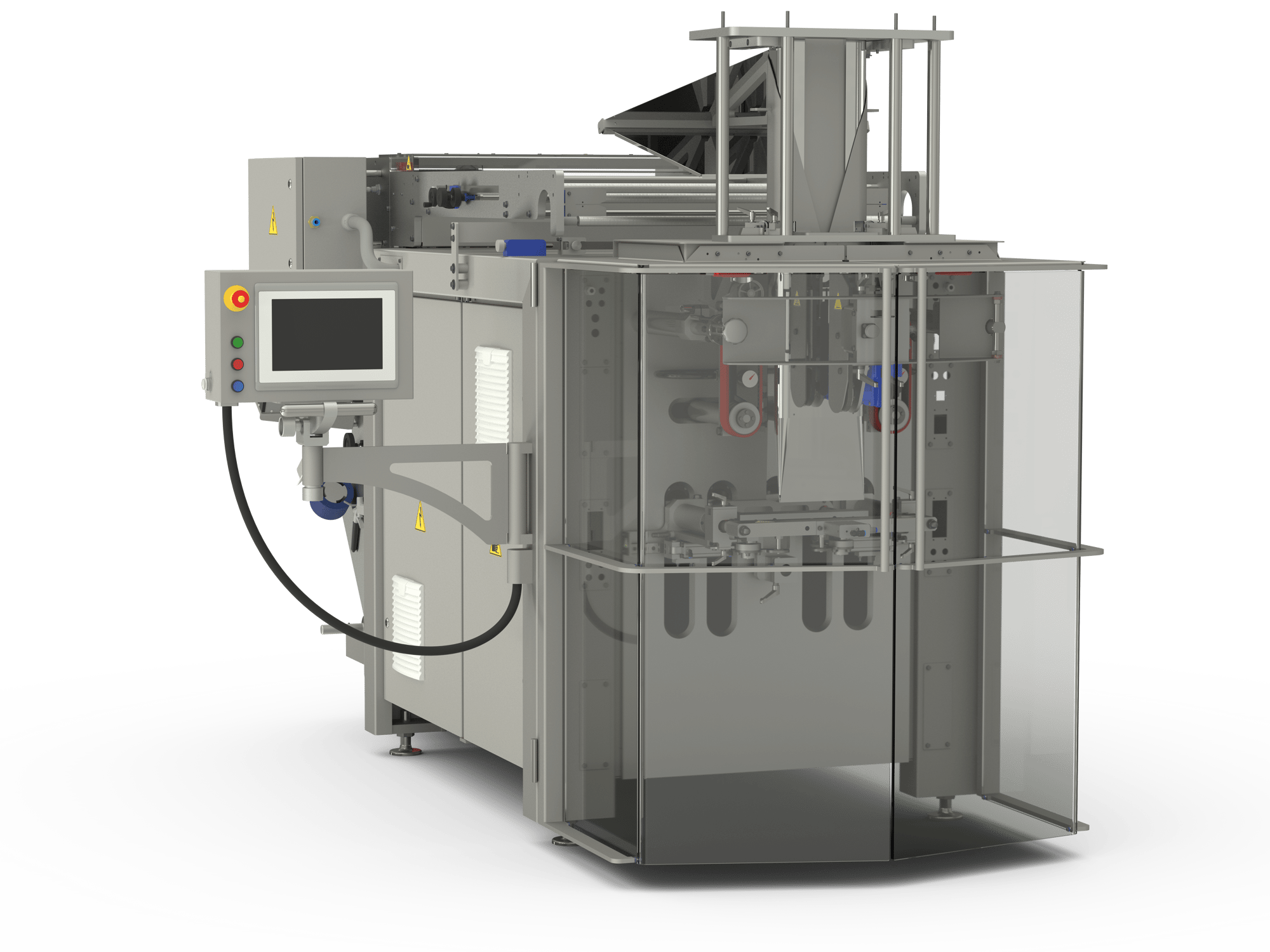

UVA Lima

- Technology: Continuous Motion

- Frame: Robust, stainless steel

- Jaw Width (mm): 250 / 320 / 400

- Machine Dimensions (w/d/h in mm): 1,200 / 2,086 / 1,875

- Machine Weight (approx.): 950 kg

- Power Supply: 10 / 12.5 kVA

- Max. Seal Pressure: 6 kN

- Compressed Air Requirement: 6 bar

- Mechanical Bag Output: 150 bags per minute

- Max. Film Roll Diameter (mm): 550

- Max. Film Width (mm): 840

- Min. Bag Size (w/d/h in mm): 50 x 30 x 50

- Max. Bag Size (w/d/h in mm): 400 x 130 x 600

- IP Standard: IP54

- Sealing Methods: Heat seal, Impulse, Ceramic seal, or combination

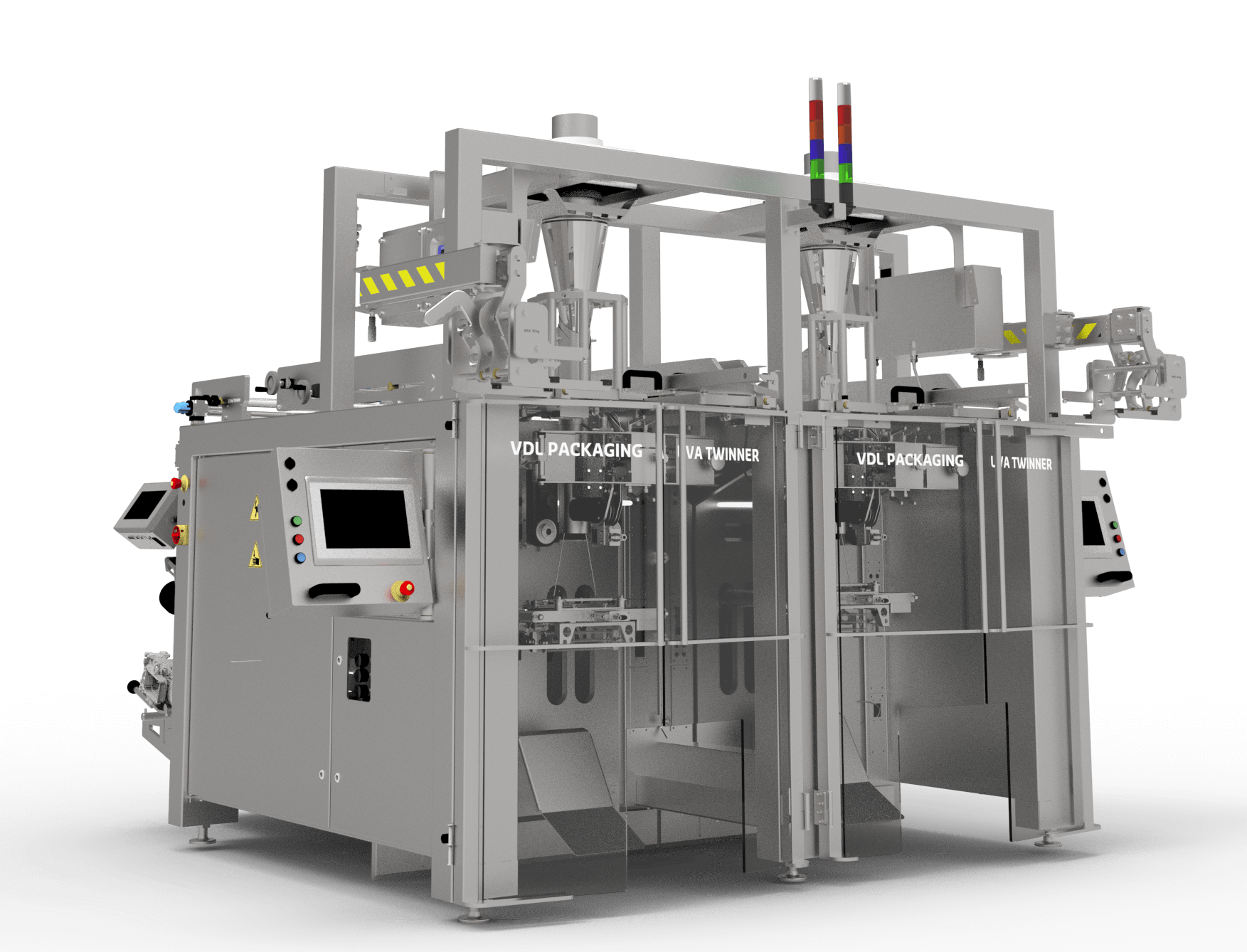

UVA Twinner

- Technology: Continuous Motion

- Frame: Robust stainless steel frame

- Jaw Width (mm): 250 / 320

- Machine Dimensions (w/d/h in mm): 2,600 / 2,600 / 1,600

- Machine Weight (approx.): 2,000 kg

- Power Supply: 20 / 22 kVA

- Pitch Distance (mm): 1,080

- Max. Seal Pressure: 6 kN

- Compressed Air Requirement: 6 bar

- Mechanical Bag Output: 2 x 200 bags per minute

- Max. Film Roll Diameter (mm): 550

- Max Film Width (mm): 700

- Min. Bag Size (w/d/h in mm): 50 x 30 x 50

- Max. Bag Size (w/d/h in mm): 320 x 130 x 600

- IP Standard: IP54

- Sealing Methods: Heat Seal (optional ceramic seal)

The Intermittent Motion Machines

Intermittent VFFS machines pause film movement during filling and sealing, allowing for precise dosing and complex packaging. Suitable for pharmaceuticals and speciality foods., they offer flexibility in bag styles and sizes.

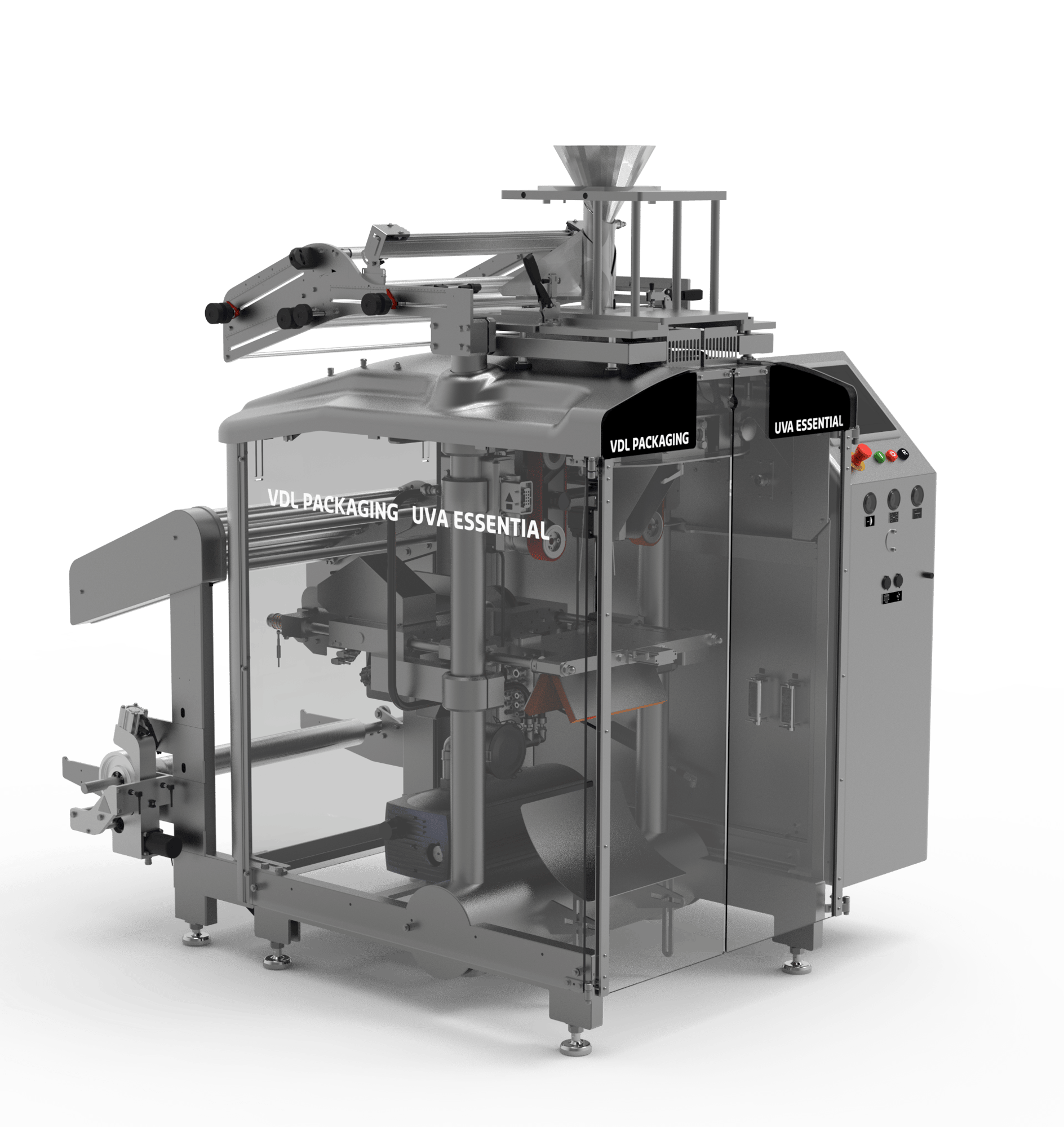

UVA Essential

- Technology: Intermittent Motion

- Frame: Stainless steel frame

- Jaw Width (mm): 320

- Machine Dimensions (w/d/h in mm): 1,810 / 2,309 / 1,730

- Machine Weight (approx.): 650 kg

- Power Supply: 7.5 kVA

- Max. Seal Pressure: 6 kN

- Compressed Air Requirement: 4 bar

- Mechanical Bag Output: 120 bags per minute

- Film Transport: Friction (vacuum optional)

- Max. Films Roll Diameter (mm): 550

- Max Film Width (mm): 670

- Min. Bag Size (w/d/h in mm): 50 x 30 x 100

- Max. Bag Size (w/d/h in mm): 320 x 120 x 470

- IP Standard: IP54

- Sealing Methods: Heat Seal (optional ceramic seal or combination)

UVA In-Motion 500

- Technology: Intermittent

- Frame: Robust, stainless steel frame

- Jaw Width (mm): 500

- Machine Dimensions (w/d/h in mm): 2,500 / 4,750 / 2,857 / H with zip unit 3,700

- Machine Weight (approx.): 3,000 kg

- Power Supply: 12.5 kVA (400 V, three phase, 50/60 Hz., 35A)

- Control System: Allen Bradley 5500 CompactLogix 12-inch HMI touch panel

- Max. Seal Pressure: 12 kN

- Compressed Air Requirement: 6 bar

- Mechanical Bag Output: 12 - 40 bags per minute

- Max. Film Roll Diameter (mm): 700

- Max Film Width (mm): 1,350

- Min. Bag Size (w/d/h mm) (Single Pull): 180 x 70 x 100

- Max. Bag Size (w/d/h mm) (Double Pull): 450 x 200 x 1,150

- IP Standard: IP54

- Sealing Methods: Heat Seal / Poly Heat Seal

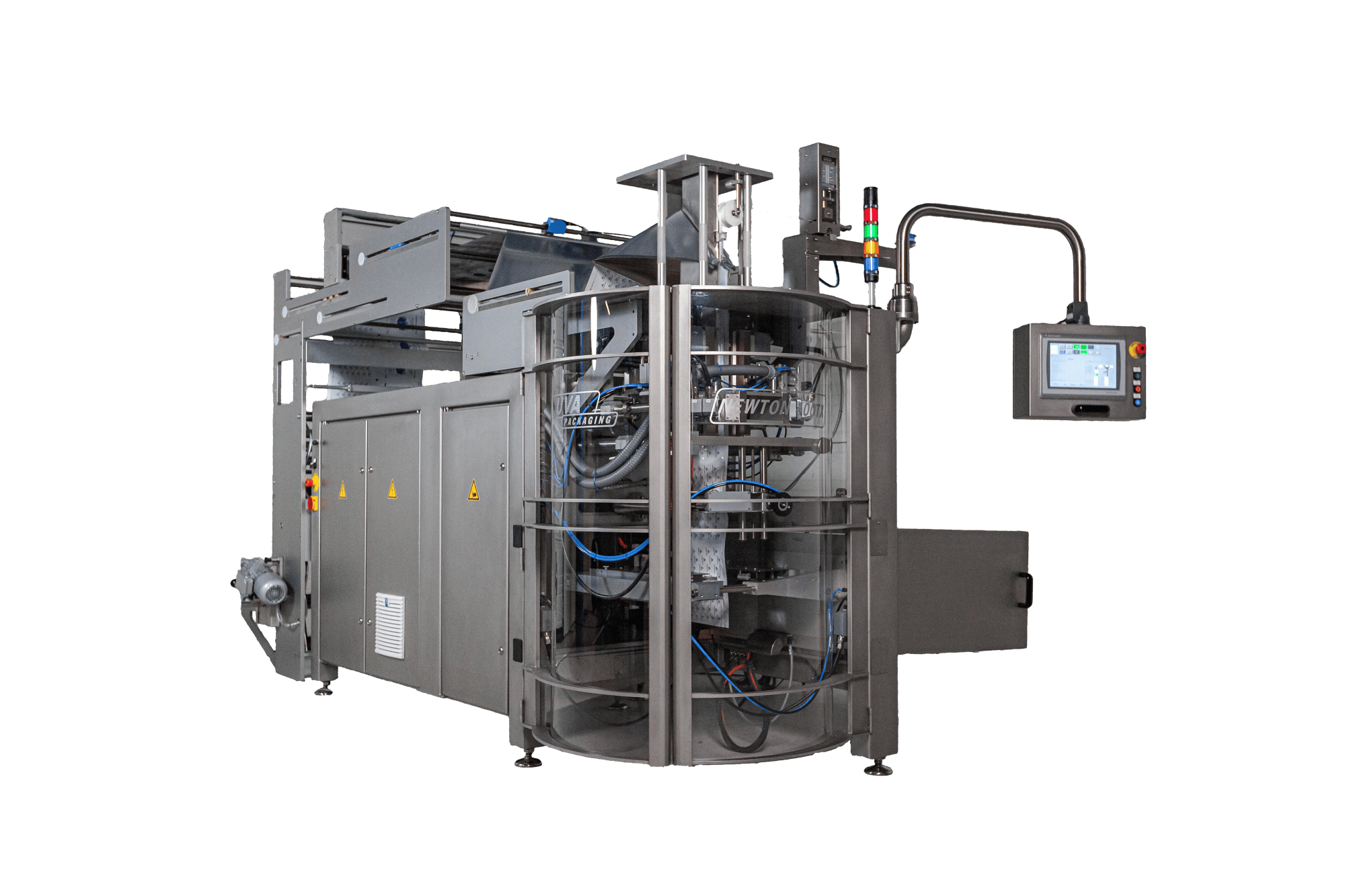

UVA Newton TX

- Technology: Intermittent Motion

- Frame: Robust, stainless steel frame

- Jaw Width (mm): 400

- Machine Dimensions (w/d/h in mm): 2,165 / 1,875 / 2,294

- Machine Weight (approx.): 1,350 kg

- Power Supply: 10 / 12.5 kVA

- Control System: Allen Bradley 5500 CompactLogix 12-inch HMI touch panel

- Max. Seal Pressure: 8 kN

- Compressed Air Requirement: 6 bar

- Mechanical Bag Output: 100 bags per minute

- Max. Film Roll Diameter (mm): 700

- Max. Film Width (mm): 840

- IP Standard: IP54

- Sealing Methods: Heat seal

Standard Position for Pillow Bags:

- Min. Bag Size (w/d/h in mm): 70 x 50 x 50

- Max. Bag Size (w/d/h in mm): 400 x 150 x 600

Turned Position for Doy Bags:

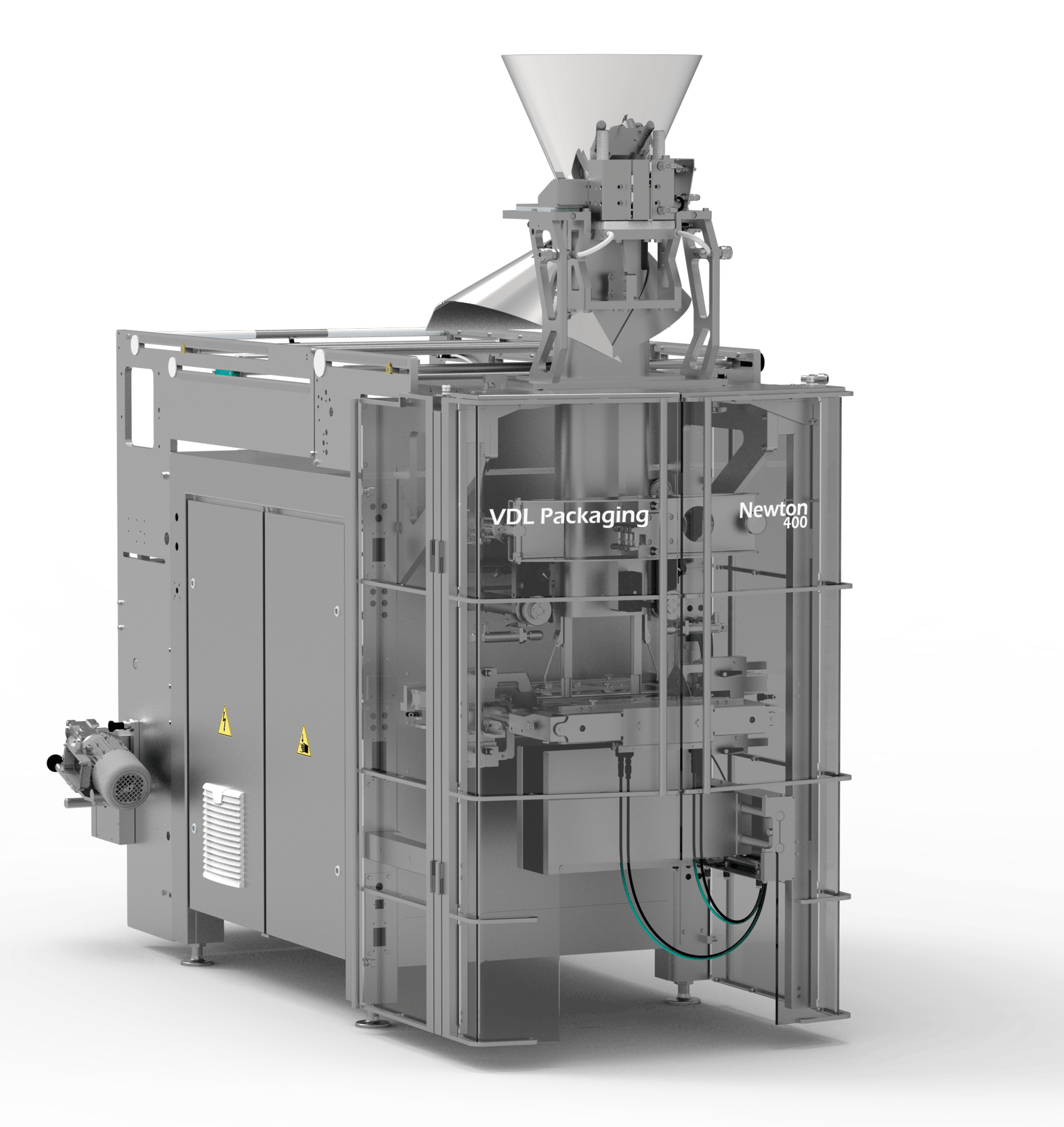

UVA Newton 400

- Technology: Intermittent Motion

- Frame: Closed, stainless steel frame

- Jaw Width (mm): 400

- Machine Dimensions (w/d/h in mm): 1,000 / 2,700 / 2,100

- Machine Weight (approx.): 950 kg

- Power Supply: 10 / 12.5 kVA

- PackML Integration: No

- Max. Seal Pressure: 8 kN

- Compressed Air Requirement: 6 bar

- Mechanical Bag Output: 120 pillow bags per minute

- Max. Film Roll Diameter (mm): 700

- Max Film Width (mm): 840

- Min. Bag Size (w/d/h in mm): 60 x 30 x 60 (Block Bottom)

- Max. Bag Size (w/d/h in mm): 320 x 180 x 600 (Block Bottom)

- IP Standard: IP54

- Sealing Methods: Heat Seal and/or impulse

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.