Non-food packaging

Not in the food business?

We can still help – our solutions have proved useful to a variety of businesses, from packing household goods and industrial components to pharmaceutical. No matter what your production requirements, due to the bespoke nature of our solutions, we’re confident we can help reduce manual processes and increase the efficiency of your line.

Our range of automated solutions offer the versatility and flexibility to suit a wide variety of product industries. We combine technical expertise with detailed knowledge of sector-specific requirements to find a solution to suit your every need.

Packaging for all styles

Consumers switched brands or product often because of presentation, ease of use or environmental concerns about how it is packaged. Could you be losing out on potential customers?

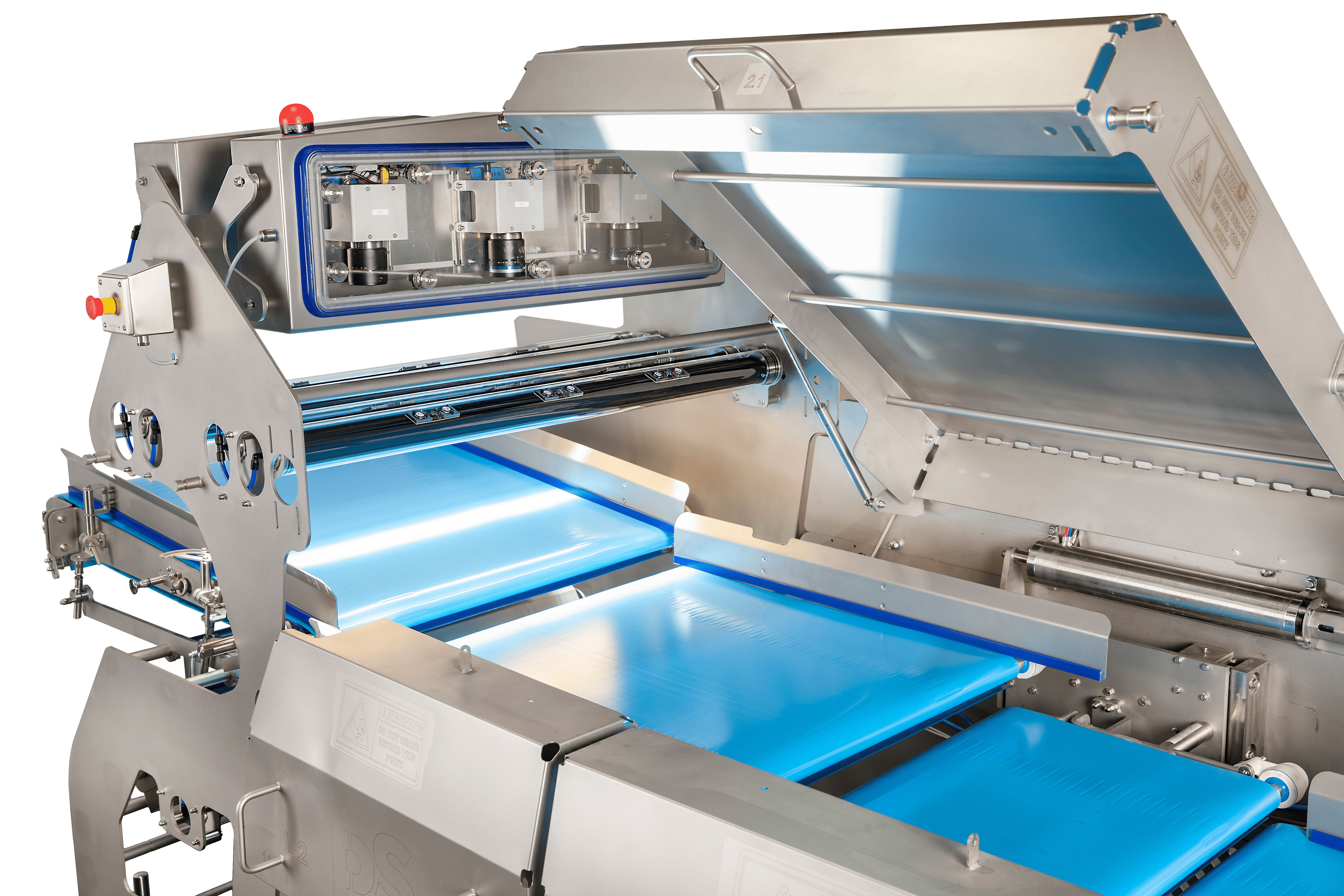

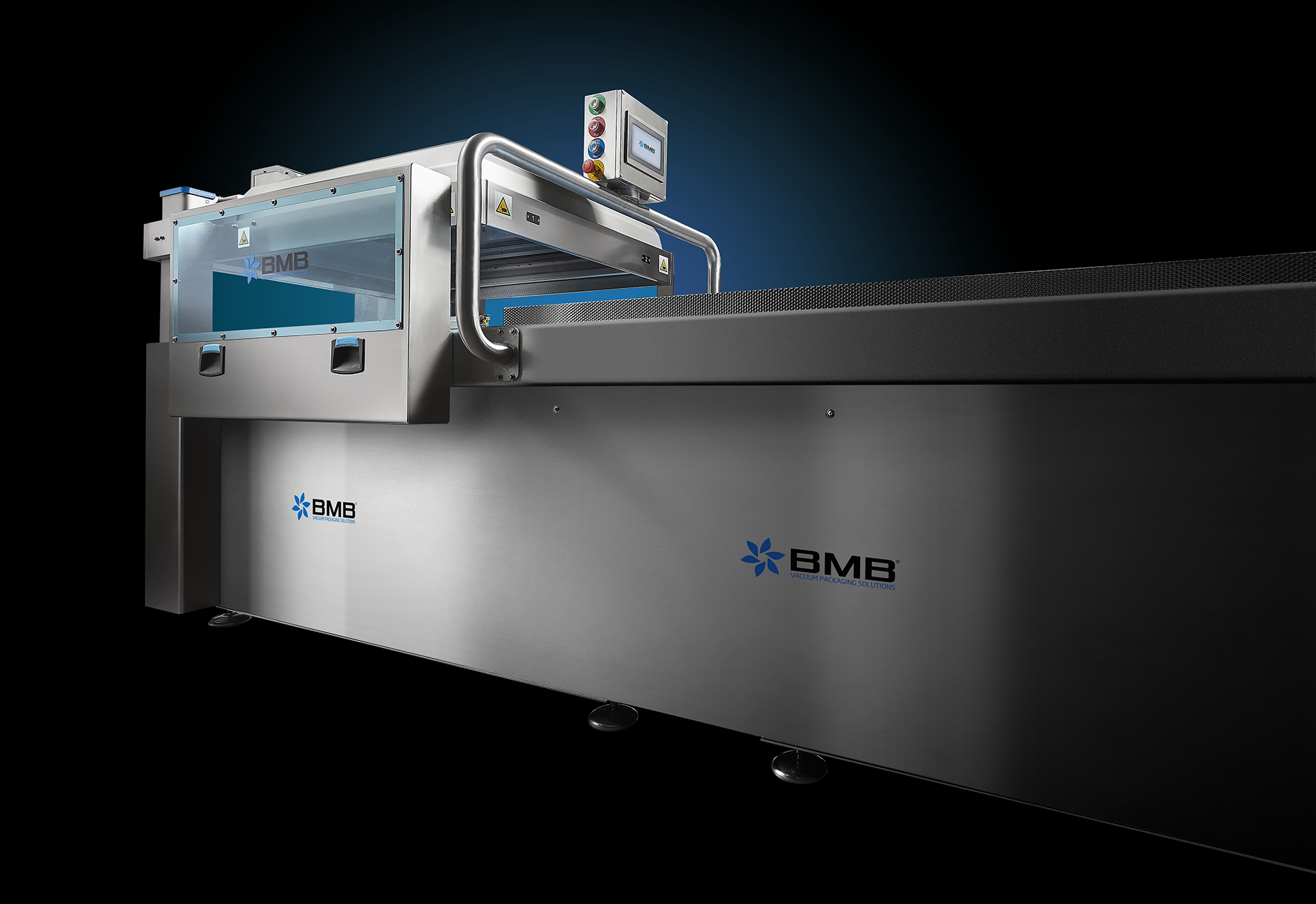

Our range of Traysealers, Thermoformers, bagmakers and flowrappers are proven on the latest mono plastics, card and paper packaging materials with superior sealing and easy opening features.

Case packing

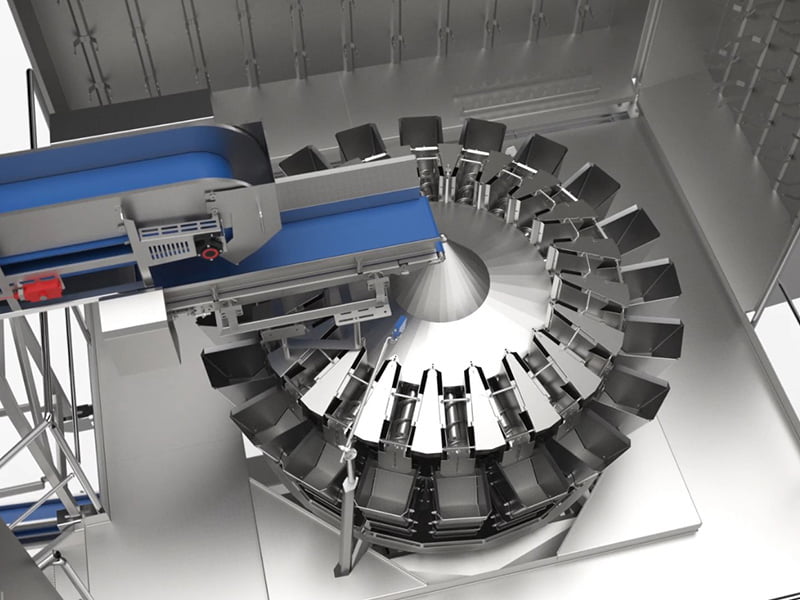

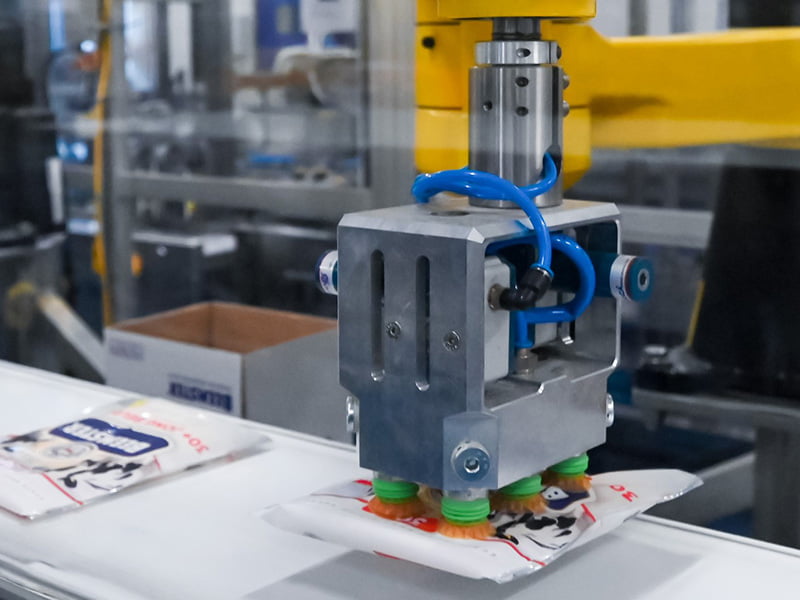

The Pick & Place robot from our partners DGS is capable of sorting and moving packed products on a continuous basis. Systems can handle all kinds of components, trays, cartons and bags into crates and boxes.

The Pick & Place robot is a smart investment that quickly pays for itself while improving the quality of your production process through a higher degree of accuracy and flexibility.

Intelligent vision camera techniques are the eye on the line and reduce the need for manual intervention allowing you to place your people in other areas of the factory.

Recommended Products

How can you benefit from our experience?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

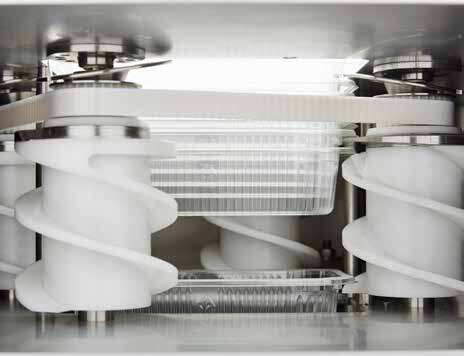

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Successfully Relocating Packaging Solutions To A New Site For A Poultry Processing Company

Relocating Packaging Solutions In A Poultry Processing Company The Challenge The challenge presented to us involved relocating three A series...

Read the full Case Study

-

Case Study

Sliced cheese line

Raising efficiency and production The Challenge Between 400 & 500 tons of cheese move through the packaging and production facility. Since the demand for...

Read the full Case Study

-

Case Study

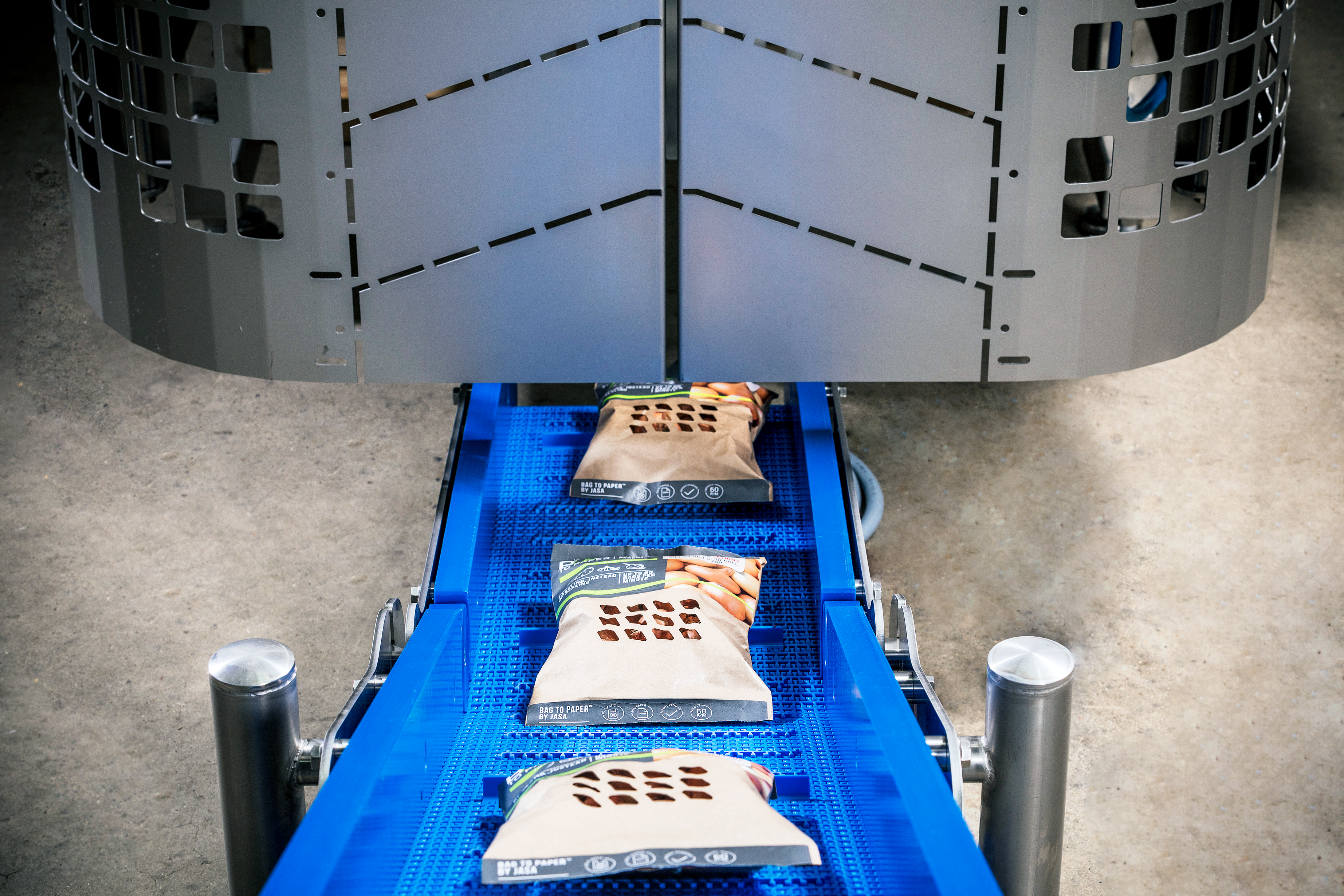

Compostable packing supplier

The perfect packaging combination The Challenge Sealpac were approached by a new customer to find a solution to a new packing concept.

Read the full Case Study

-

Case Study

Easy-to-open sliced salmon packs

Seafood at its best The Challenge The customer had developed a new process for producing smoked salmon slices as an alternative to meats in sandwiches....

Read the full Case Study